Die casting for perfect aluminium cast parts

Die casting is used for the production of light metal parts, in particular produced from aluminium alloys.

The liquid aluminium melt is poured into a permanent metal mould, also referred to as a die.

With the established casting process of low pressure die casting and gravity tilting die casting, cast parts can be produced in accordance with the highest quality demands and efficiently in a range of series sizes.

Depending on the specific requirements, the system concepts vary in their degree of automation and system scope.

Compared to sand casting, die casting delivers shorter solidification times through the use of a permanent metal mould, as well as improved material characteristics with regards to dimensional accuracy, surface quality, density, strength and stiffness.

The process

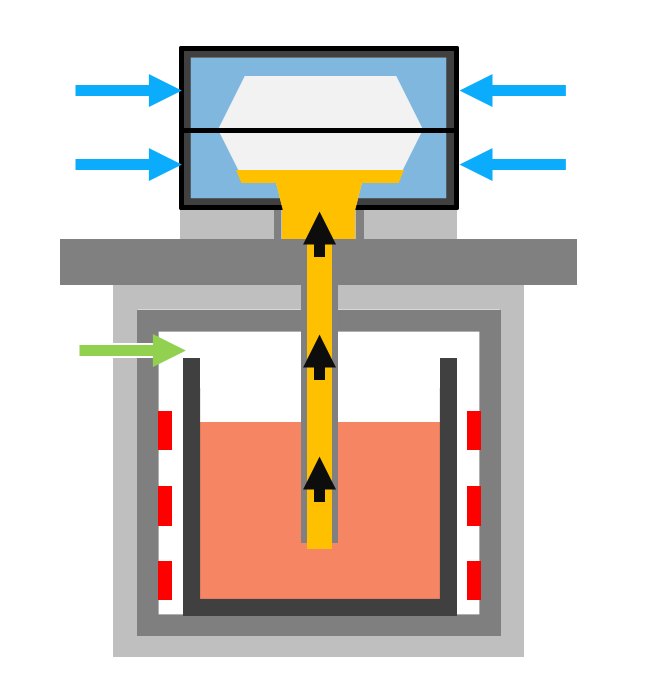

Liquid aluminium melt rises into a permanent metal mould through a riser pipe due to the pressurisation of a holding furnace.

During the solidification process, the furnace pressure remains constant and is supported by air or water cooling.

The mould parts are subsequently opened and the cast part is ejected.

Fig.: Schematic representation of low pressure die casting

The principle

Low pressure die casting enables the production of high quality aluminium cast parts through uniform mould filling of the die.

Individually adjustable parameters guarantee a controlled and reproducible casting process.

Pressurising the die against the direction of gravity, in combination with targeted die cooling, results in optimum solidification.

Depending on the shape of the cast part, in particular with cross-section transitions, it is possible to individually align the casting speed.

The formation of oxide skins, cold laps and air inclusions is kept to a minimum.

Extremely dense feeding of the cast part is achieved with an overpressure of max. 1 bar and holding until the cast part has solidified.

By reducing the size of the gating system you save cycle materials and reduce your costs for unnecessary cleaning, rework and the remelting of cast parts.

The advantages

- Better material characteristics through:

- Uniform, controlled mould filling

- Dense feeding

- Reduction in oxide and gas absorption

- Reduction in the cycle material

- Shortening of process times through process automation and reproducibility

- Cost savings

- Better material characteristics through: