Innovative in design – Powerful in performance

The new product range encompasses the tilting casting machine of type “PLS-I & II”, as well as the low pressure casting machine of type “LPD-II”.

Building on the experience and expertise of the Sinto Group, with over 680 successful machine installations, in the future it will be possible to realise flexible and individual system concepts in more than sand casting alone.

With the new machine range from Heinrich Wagner Sinto we are offering you the possibility of also producing high quality cast pieces with aluminium gravity die casting!

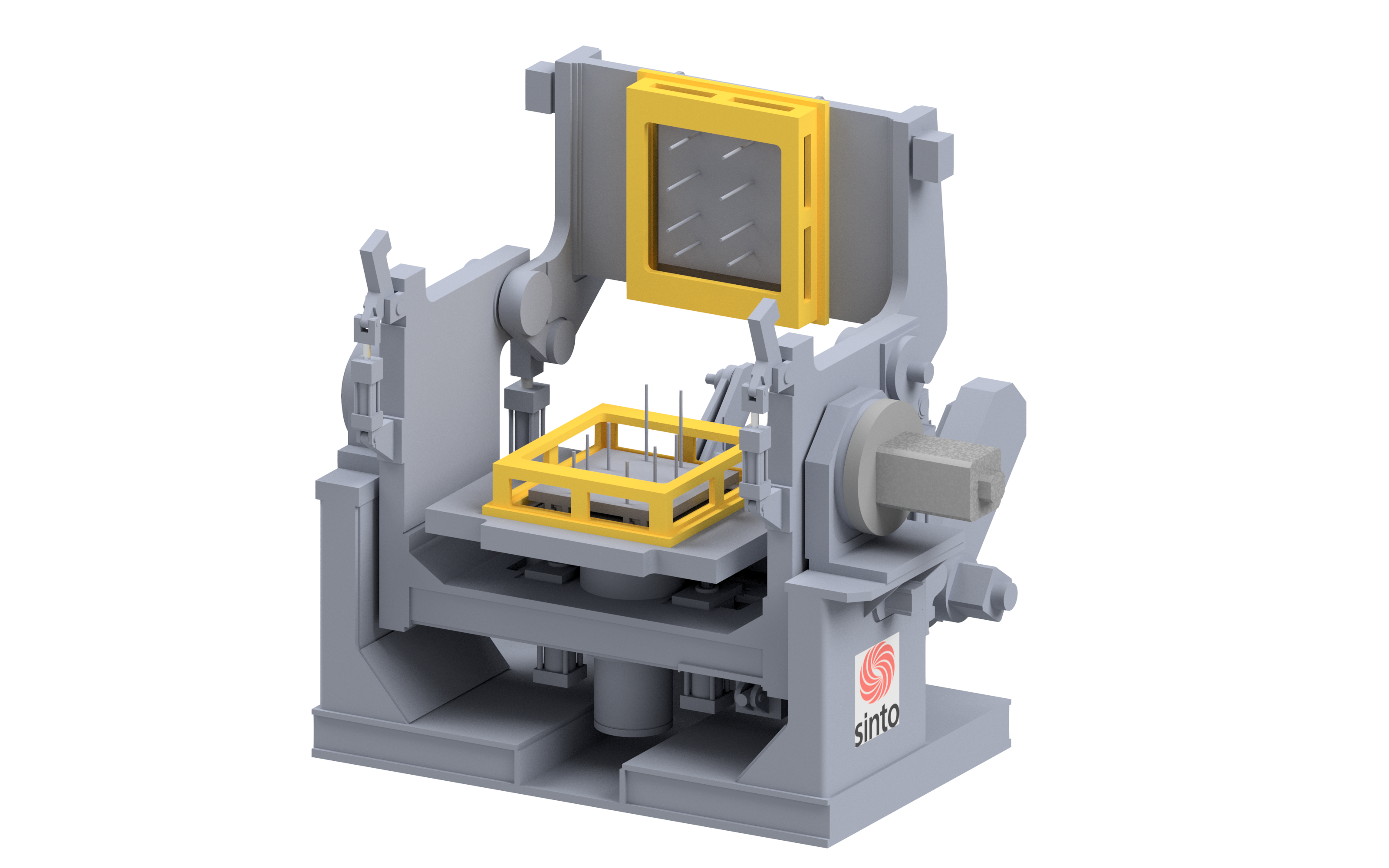

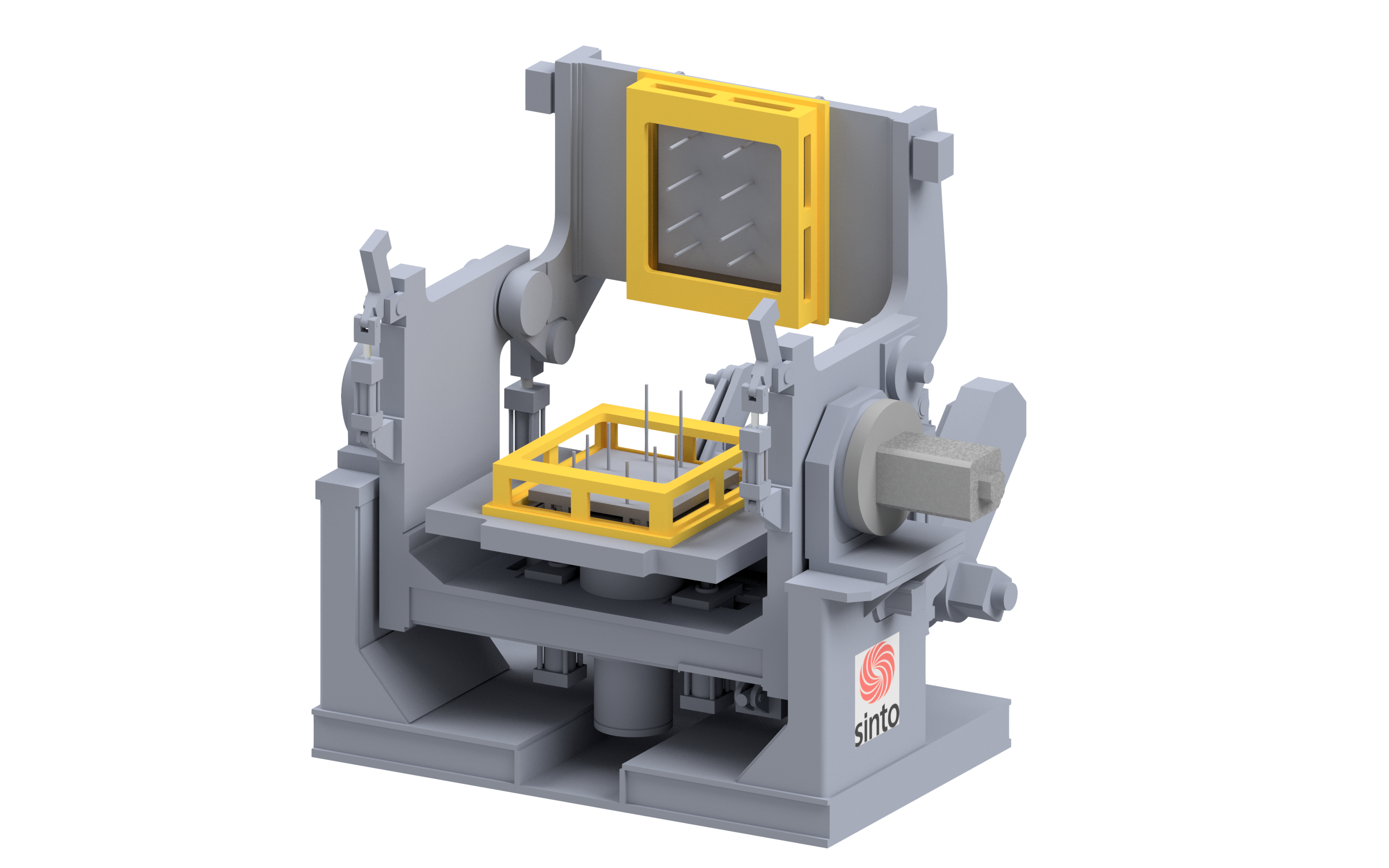

Gravity tilting casting machine “PLS-I & II”

Your advantages

- Compact and stable machine design

- Powerful closing and opening unit

- Precise control of the tilting movement

- Independent control of casting ladle and die

- Energy efficient

Your gains

- High quality aluminium casting

- Less space required

- Ergonomic operation

- Energy savings

- Cost savings

Performance specifications PLS-I PLS-II External dimensions (mm) 2050 x 2050 x 2000 2300 x 2450 x 2400 Upper fixing plate (mm) 980 x 620 1250 x 620 Lower fixing plate (mm) 920 x 700 1200 x 800 Die closing force (kN) 50 (at 55 bar) 80 (at 55 bar) Die opening force (kN) 75 (at 100 bar) 115 (at 100 bar) Ejection force (kN) 50 (at 100 bar) 80 (at 100 bar) Drive Servo Motor Tilting angle (º) 0 to 105 Tilting speed (º/sec) 16 18 Machine control Siemens S7 Subject to technical changes.

The design

The tilting casting machine from the PLS-series is a fully automatic casting machine for filling your die. Depending on the die size, the casting machine is available in two sizes “PLS-I” and “PLS-II”, with varying dimensions, as well as closing and opening forces. The centrally located machine pivot point in combination with the precisely controllable servo drive guarantees even and smooth die filling, which minimises the oxide and gas absorption during the casting process.

The characteristics of the tilting motion can be individually adjusted to your requirements by varying the tilting speed and behaviour. In connection with the optional rotating casting ladle, it is possible to satisfy the highest quality demands. Rotating the tilting casting machine is controlled here independent of the casting ladle rotation. This gives you greater flexibility for your casting process. The compact and robust design with the pivoting machine top section guarantees economical and ergonomically efficient system operation.

Linear and rotary table configurations can also be realised for maximum productivity.

Optional

- Swivelling and rotating casting ladle

- Automation solutions for core insertion, casting ladle filling and cast part removal

- Heating, changeover and emptying station for the casting ladle

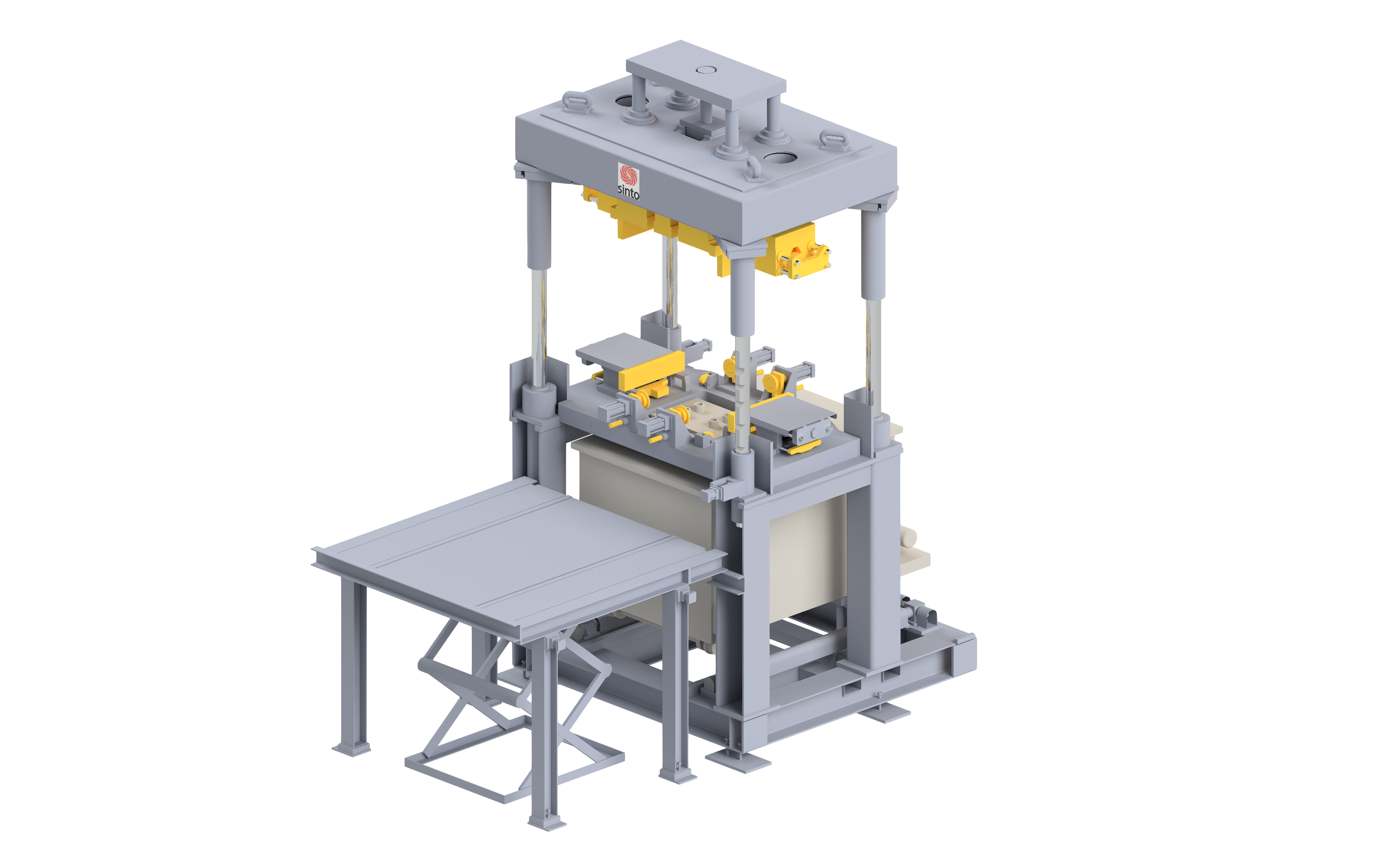

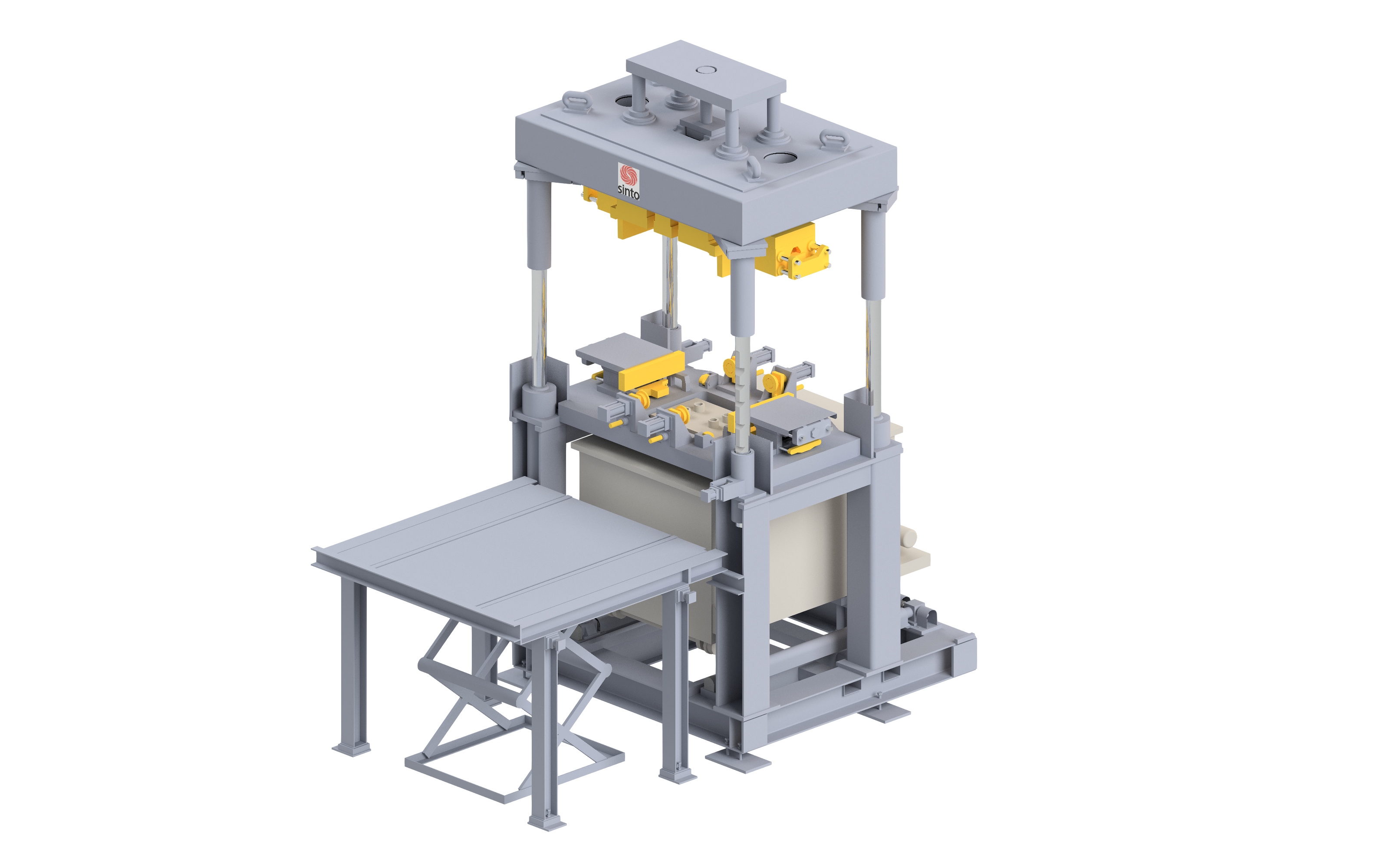

Low pressure casting machine “LPD-II”

Your advantages

- Compact and stable machine design

- Powerful closing and opening unit

- High removal precision

- Energy efficient

Your gains

- High quality aluminium casting

- Less space required

- Ergonomic operation

- Energy savings

- Cost savings

Performance specifications

LPD-II External dimensions (mm) 7000 x 4500 x 5600 Upper fixing plate (mm) 2040 x 1000 Lower fixing plate (mm) 2500 x 1400 Die closing force (kN) 180 (at 100 bar) Die opening force (kN) 250 (at 100 bar) Ejection force (kN) 250 (at 100 bar) Opening height (mm) 1200 Closing height (mm) 400 Furnace heating Resistance-heated Furnace fill quantity (kg) 800 Machine control Siemens S7 Subject to technical changes.

The design

The low pressure casting machine LPD-II offers a whole new machine design.

With the mobile top machine gantry, it is particularly compact and efficient. The highly robust and stiff closing and opening unit with centrally positioned powerful hydraulic cylinder guarantees high removal precision and reduces the mould draft angles when opening and closing your die.

You gain precision where you need it, and you can proceed quickly with your casting process with a rapid, long opening stroke of the entire machine unit with two diagonally arranged hydraulic cylinders in the base frame of the low pressure casting machine.

Additionally, the mobile machine gantry permits good accessibility to important valve units and increases the operation and maintenance-friendliness of the casting machine.

The compact machine design also offers advantages when it comes to transport and first commissioning.

You save time and money.

Optional

- Various furnace systems

- Automation for core insertion, cast part removal and die changes

Cooling system for die casting

Your advantages

- Air and water cooling

- Time and temperature control

- Controlled cooling circuits

Your gains

- Targeted temperature management of the die

- Better material characteristics

- Short cycle times

Precise cooling controls individually adaptable to the cast part-specific requirements enable effective dissipation of the melt heat and control of the heat balance of your die.

In addition to the directed solidification, the high thermal conductivity results in shorter solidification times for the cast part and thereby shortened cycle times for the complete casting process.

The positive effects on the characteristics of your cast parts are:

- Finer and denser structure

- Enhanced mechanical characteristics

- Greater density

- Improved surface quality

It is possible to choose between air and water cooling for cooling your die. The cooling circuits can be controlled by time or temperature. The control type and number of cooling circuits depend on the cast part and are designed in accordance with your requirements. If required, proportional valves control and regulate the individual cooling circuits. The specific cooling parameters are set here via a closed loop circuit with continuous target/actual comparison, and are automatically adjusted if necessary.

Visualisation of the casting and process data increases process reliability and guarantees the production of high quality aluminium cast parts.

Reproducible processes and data acquisition are possible through the management and storage of casting recipes and machine parameters.