The following products are available for a range of automation levels and pouring quantities:

- P-series is a pouring machine for semi and fully-automatically controlled casting for all grades of iron and light metals.

- GIMA is a basic machine for manual casting for all grades of iron and light metals.

- FVN is a pouring machine for semi or fully-automatically controlled casting for all grades of iron.

Leading-edge system and automation technology, as well as data communication with a superior ERP and QA system and data coupling naturally take place in accordance with the latest communication standards.

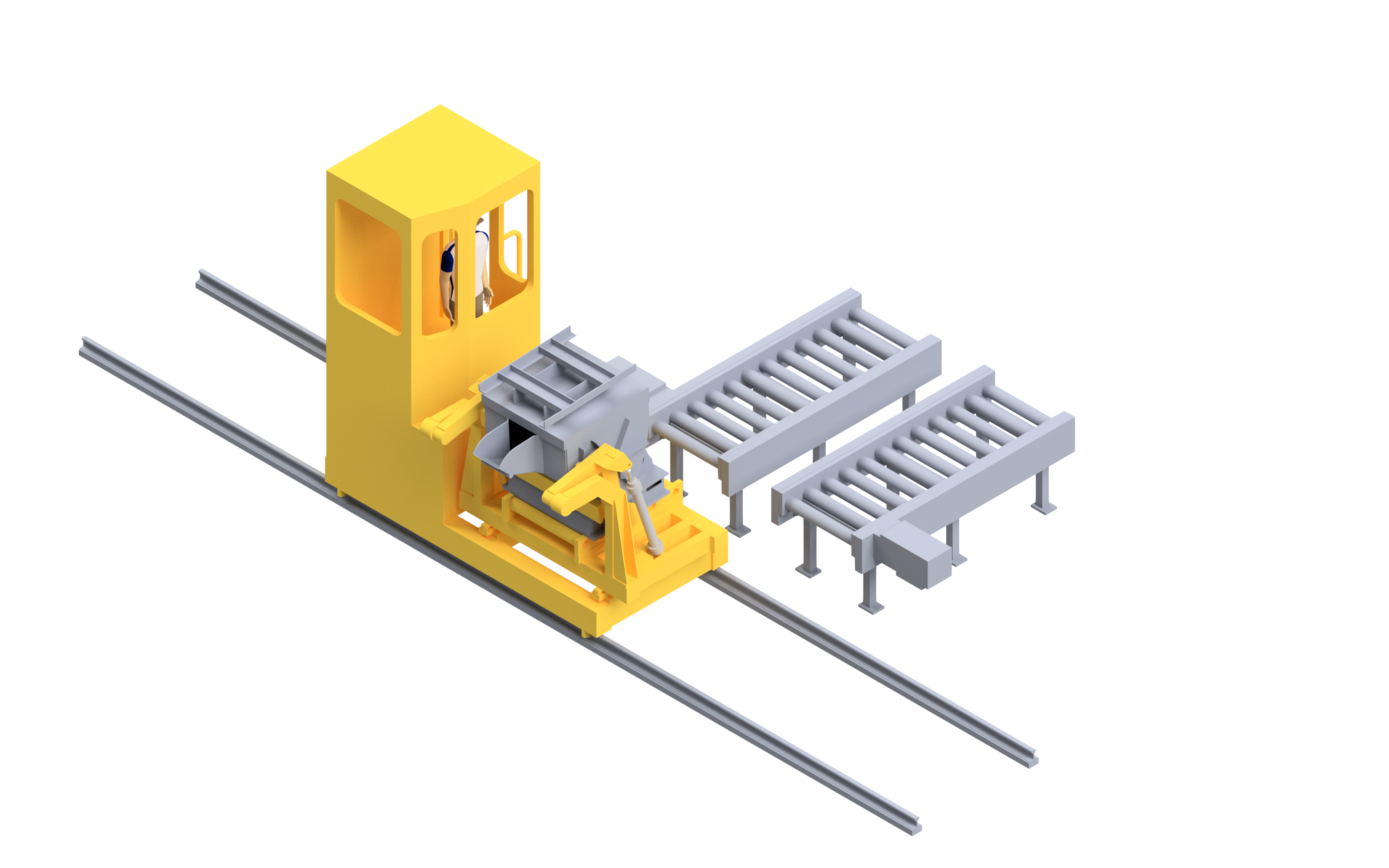

GIMA-series casting machine

Table

Type Ladle contents Dimensions X Y Z kg mm mm mm GIMA 8 500 – 900 1400 5000 2800 GIMA 12 1000 – 1500 1400 5000 2800 Deviations possible depending on ladle size.

GIMA is a basic machine for manual casting, which is intended to replace the manual casting of grades of iron such as grey cast iron, spheroidal graphite iron or vermicular iron with a crane, forklift truck or monorail.

Technical information:

- All drives of the basic machine are hydraulic drives that are controlled by the machine operator with a hydraulic joystick.

- Casting takes place by manually tilting the ladle with a joystick.

- The ladle retainer is a hydraulic tilting device that tilts the ladle about the centre point of the outer radius of the pouring nozzle.

- The GIMA can be moved along the casting line in order to guarantee continuous pouring, whilst the casting line is stationary.

- With the basic machine, the ladle can be replaced directly on the machine with the aid of a crane or forklift truck.

- Casting temperature measurement is possible with a pyrometer.

- Additional inoculant fixtures with an inoculant tank are possible.

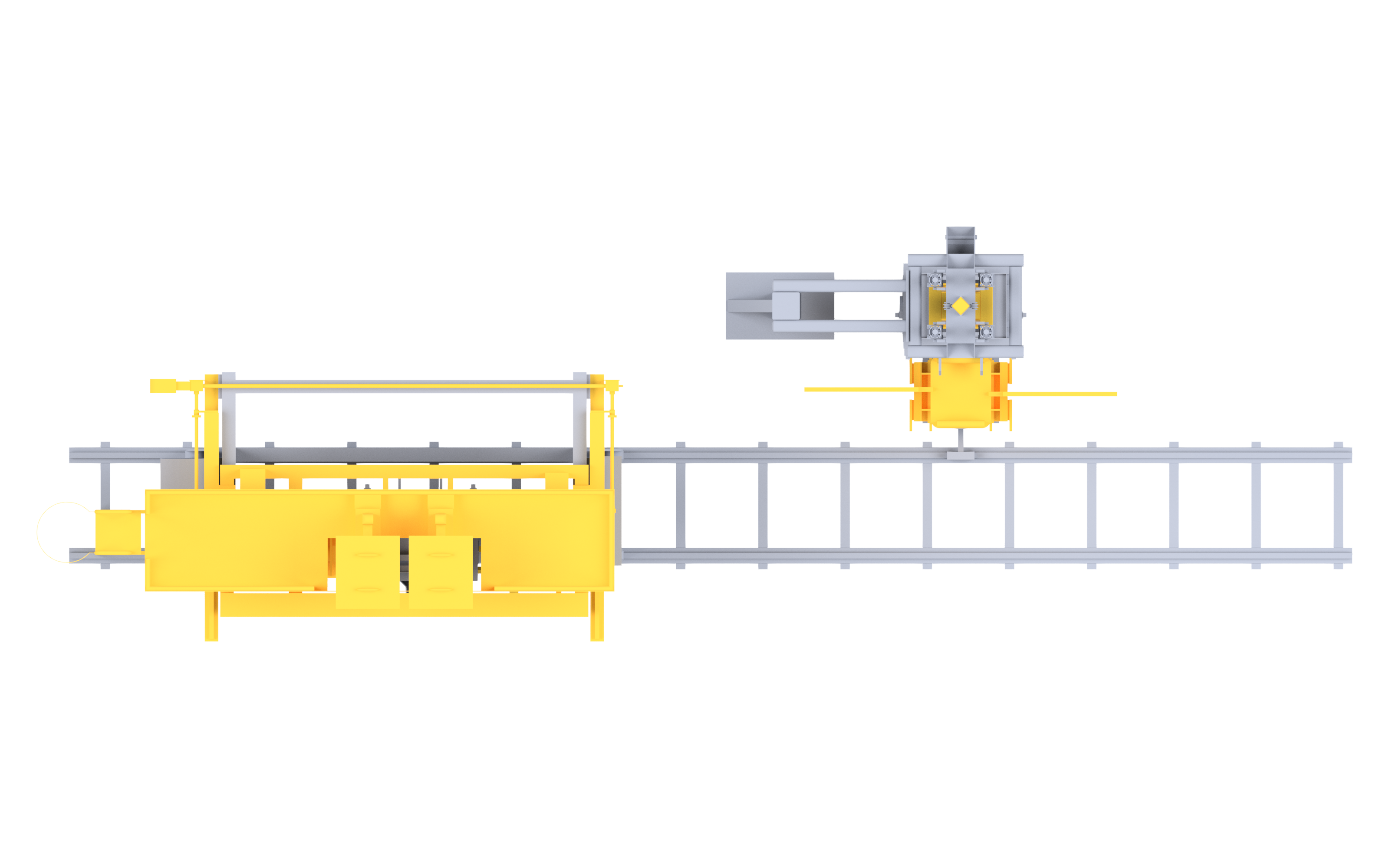

Technical drawing

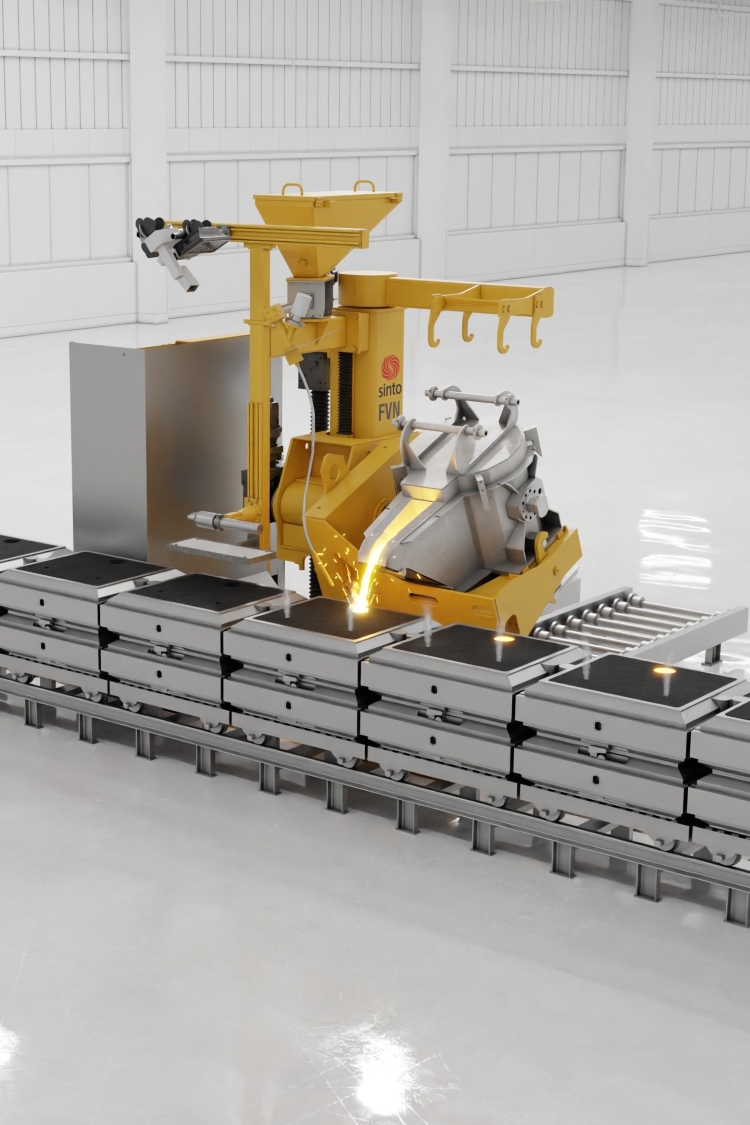

FVN-series casting machine

Table

Type Ladle contents Dimensions X Y Z kg mm mm mm FVN-III 600 – 1000 2300 3800 3700 Deviations possible depending on ladle size.

FVN is a pouring unit for the semi-automatic and fully automatic pouring of various iron grades.

Technical information:

All drives of the basic machine are brushless synchronous servo drives that are controlled by a PLC and a microcontroller.

- The ladle retainer is a tilting device driven by a brushless drive that tilts the ladle around the centre point of the outer radius of the pouring nozzle, by driving the swivelling and tilting axes at the same time. The simultaneous control of the movements therefore takes place with 3 axes:

1st axis – lateral adjustment for the start-up

2nd axis – swivelling for positioning

3rd axis – tilting and casting- In the 3rd axis casting takes place. The tilting device tips the ladle about a constant virtual point (referred to as the VN point = Virtual Nozzle)

- The pouring process is done precisely with a constant metal flow and is repeatable which ensures a high casting quality and a sustainable use of materials.

- Monitoring of filling level and pouring process is realised by the interaction of various sensors.

- The Siemens S7 control system and the pouring machine monitoring system G.L.S. 2010 provide extensive setting, transfer and processing options of the pouring parameters.

- In addition, an individual exchange of various pouring parameters with the moulding system is optionally possible according to your needs.

- The FVN unit can travel along the pouring line on a rail system to the next pouring position. Also, synchronous pouring is possible as an option.

- Ladle change is realised by means of roller conveyors.

- Measurement of pouring temperature by pyrometer is possible as an option.

- Additional inoculation devices with an inoculant tank are possible.

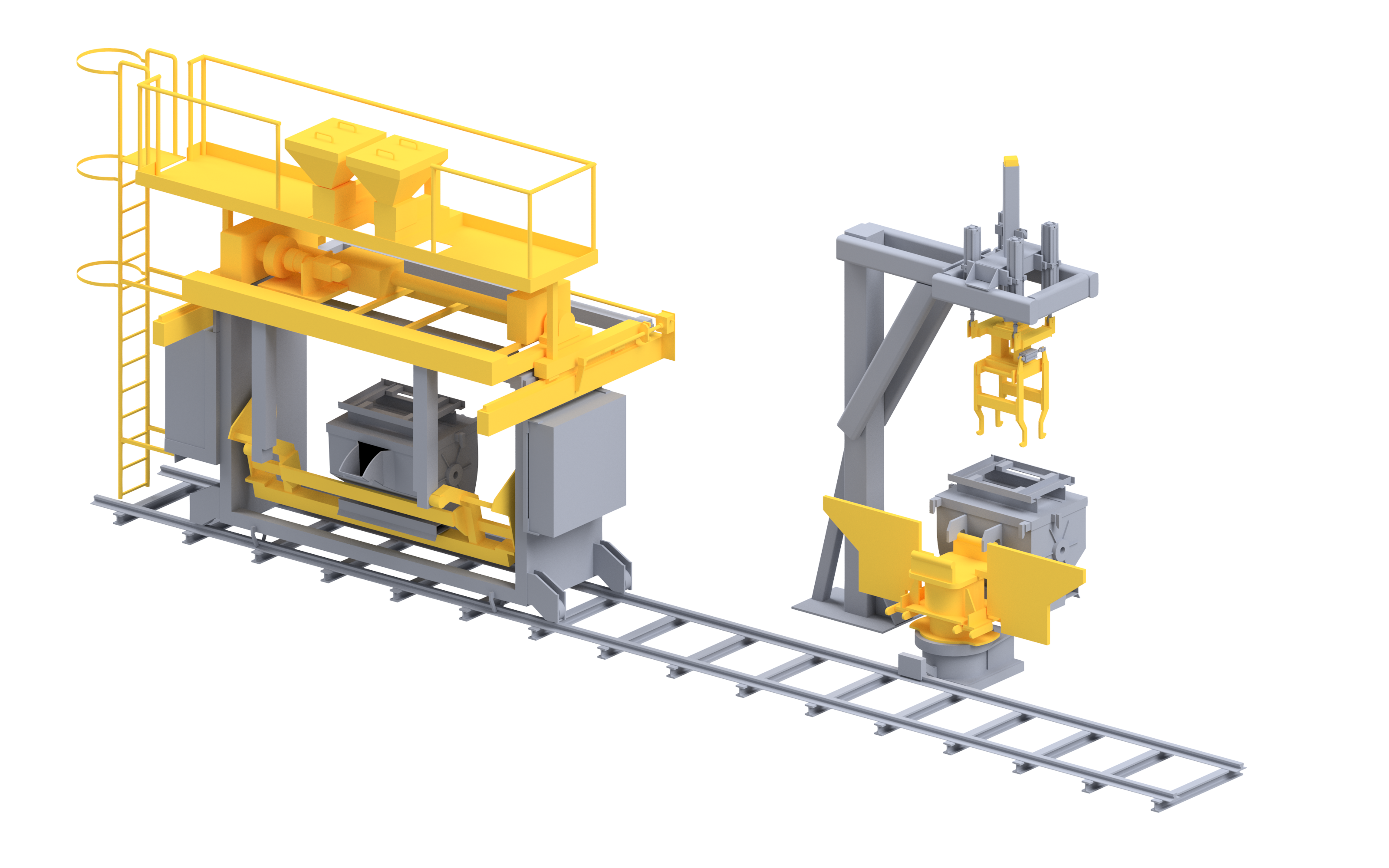

P-series casting machine

Table

Type Ladle contents Dimensions X Y Z kg mm mm mm P 10-W 600 – 1400 2000 5700 4000 P 20-W 1400 – 2400 2400 6200 4400 P 30-W 2400 – 3200 2600 6500 4800 Deviations possible depending on ladle size.

The P-series is a pouring machine for semi-automatic and automatically controlled casting of iron grades such as grey cast iron, spheroidal graphite iron or vermicular iron.

Technical information:

- All drives of the basic machine are brushless synchronous servo drives that are controlled by a PLC and/or a joystick.

- The ladle retainer consists of a brushless tilting device that tilts the ladle on the basis of the construction plan about the centre point of the outer radius of the spout.

- Casting takes place by tilting the ladle with converter-controlled tilt drives. Level control is based on a camera and the weight-dependent control with the specification of a theoretical target casting time facilitates reproducible casting.

- The P-series can be supplied with a travelling ladle turntable (type W) or with a stationary ladle turntable (type S), depending on the internal iron logistics and the exchange of the casting ladle at the machine.

- All P-machines can be moved along the casting line, in order to guarantee continuous pouring.

- The P-series is controlled with a Siemens S7-300-Technology PLC and has its own casting machine guidance system referred to as the G.L.S. 2010.

- Together with the integrated weighing system and the 2 industrial high speed cameras, the PLC offers the possibility of “weight and level-controlled casting” and the option of time-controlled casting.

- After adjusting the template-dependent casting parameters, it is possible to perform a fully automatic, level-optimised casting process.

- This process is independent of the fill height in the ladle. The entire process is automatically controlled from the first to the last pour from a ladle.

- The casting temperature is constantly measured with a pyrometer.

- Apart from the rotating ladle turntable, the ladle can be replaced with the aid of a crane or forklift truck. Or the ladle can be refilled directly without replacement.

- The P-series can be expanded for every requirement in accordance with customer wishes:

- Automatic height adjustment of the casting position

- Additional inoculant fixtures; up to five inoculant tanks possible

- Ladle cover repository

- Extension of the base rail system and simultaneous travel during casting

- Data exchange with the mould system (in addition to the standard signal exchange)

Technical drawing