Flask moulding machines and moulding lines

The requirements placed on cast parts, in particular dimensional accuracy, repeatability, surface quality and the constantly high demands on the mouldability of the most complex models requires the maximum in mould quality, which is facilitated by the different HWS moulding processes. The following methods are available:

- SEIATSU airflow squeeze moulding process

- SEIATSU.plus (model-side pressing)

- SEIATSU aeration technology ACE

Available moulding machines that utilise the aforementioned processes include not only fully-automatic high performance moulding machines, but also simple series moulding machines for manual and semi-manual operation. The following types of moulding machines are included in the HWS range:

Lifting moulding machines type HSP / HSP-D

Table

Type Max. moulding flask interior dimensions in mm Max. output approx. cpl. moulds/h HSP-1D 650 x 500 70 HSP-2D 800 x 650 60 HSP-3D 1000 x 800 50 HSP-4D 1250 x 1000 40 Deviations possible depending on moulding flask size.

HSP

Lifting moulding machine with roller lifting and with model turning table for manufacturing cope and drag part moulds, equipped with level or elastic pressure plate or water cushion.

Sand filling via conveyor belt with manual intervention option.

Moulding flask transportation manual on roller tracks or with lifting gear.

Turn-key machine with integrated hydraulics and electronic control system.

HSP-D

Lowering moulding machine with model turning table for manufacturing cope and drag part moulds, equipped with level or elastic pressure plate or multi-stamp press.

Sand filling via conveyor belt with manual intervention option or metering device.

Moulding flask transportation by hydraulic cylinder on roller tracks.

Turn-key machine with integrated hydraulics and electronic control system.

Technical drawing

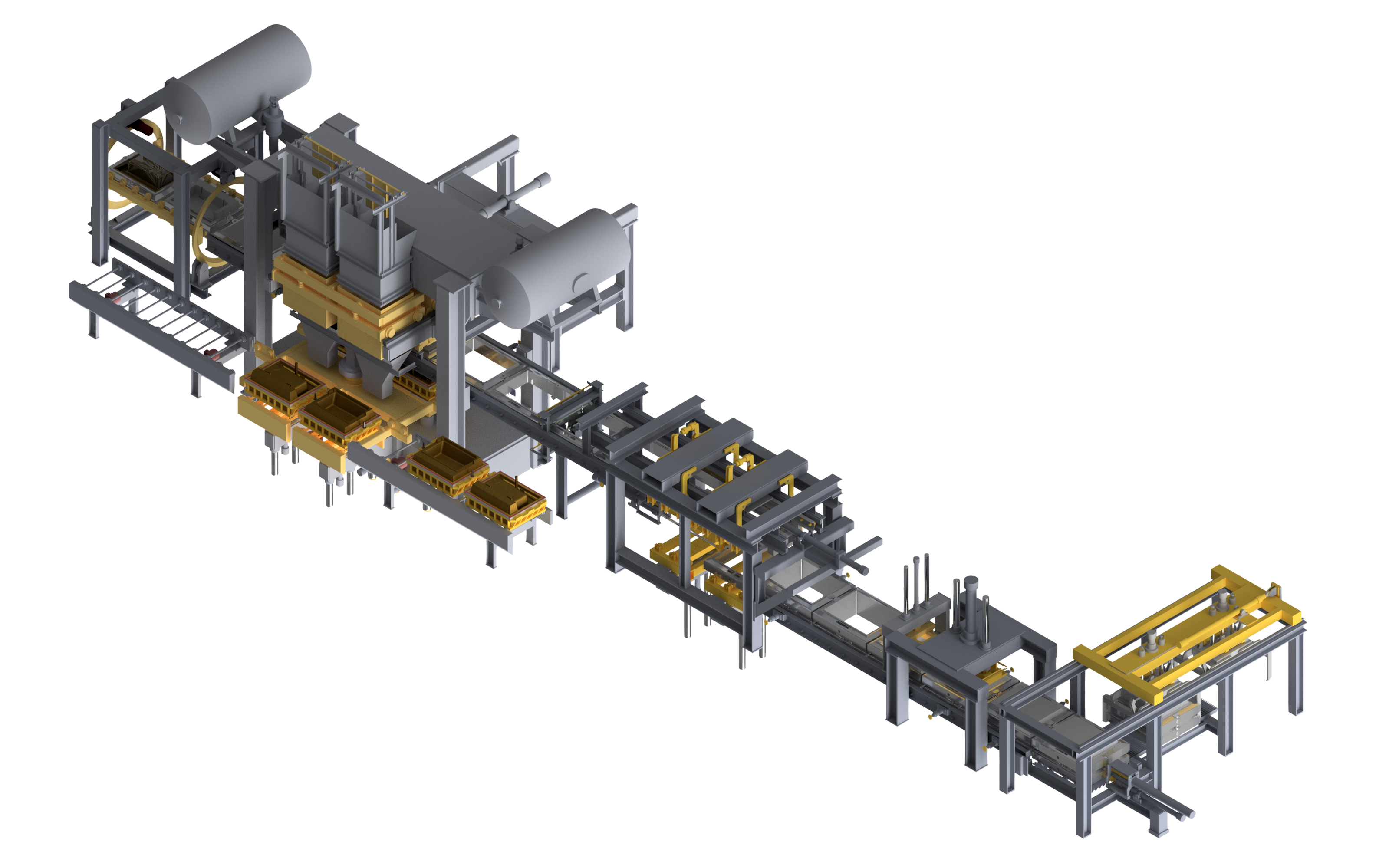

Lowering moulding machine type DAFM-S / DAFM-SD

Table

Type Cpl. moulds / hour DAFM-SD up to 70* *Depending on the respective moulding flask size.

DAFM-S

Lowering moulding machine with model roller track for manufacturing one mould half respectively, equipped with level or elastic pressure plate or multi-stamp press.

Sand filling via conveyor belt with manual intervention option or metering device.

Moulding flask transportation with hydraulic cylinder on roller tracks.

DAFM-SD

Lowering moulding machine with model turning table for manufacturing cope and drag part moulds, equipped with level or elastic pressure plate or multi-stamp press.

Sand filling via conveyor belt with manual intervention option or metering device.

Moulding flask transportation with hydraulic cylinder on roller tracks.

Technical drawing

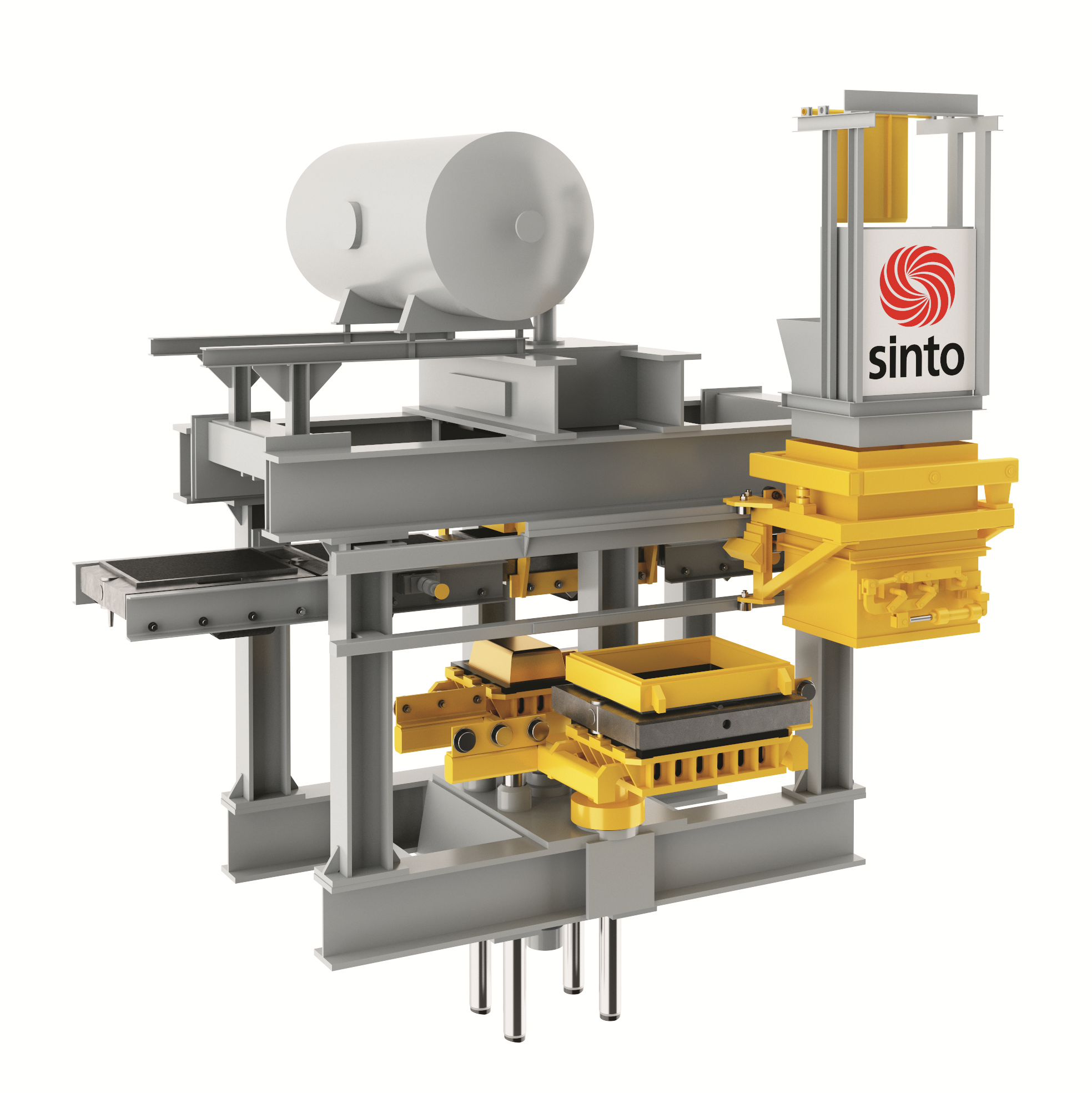

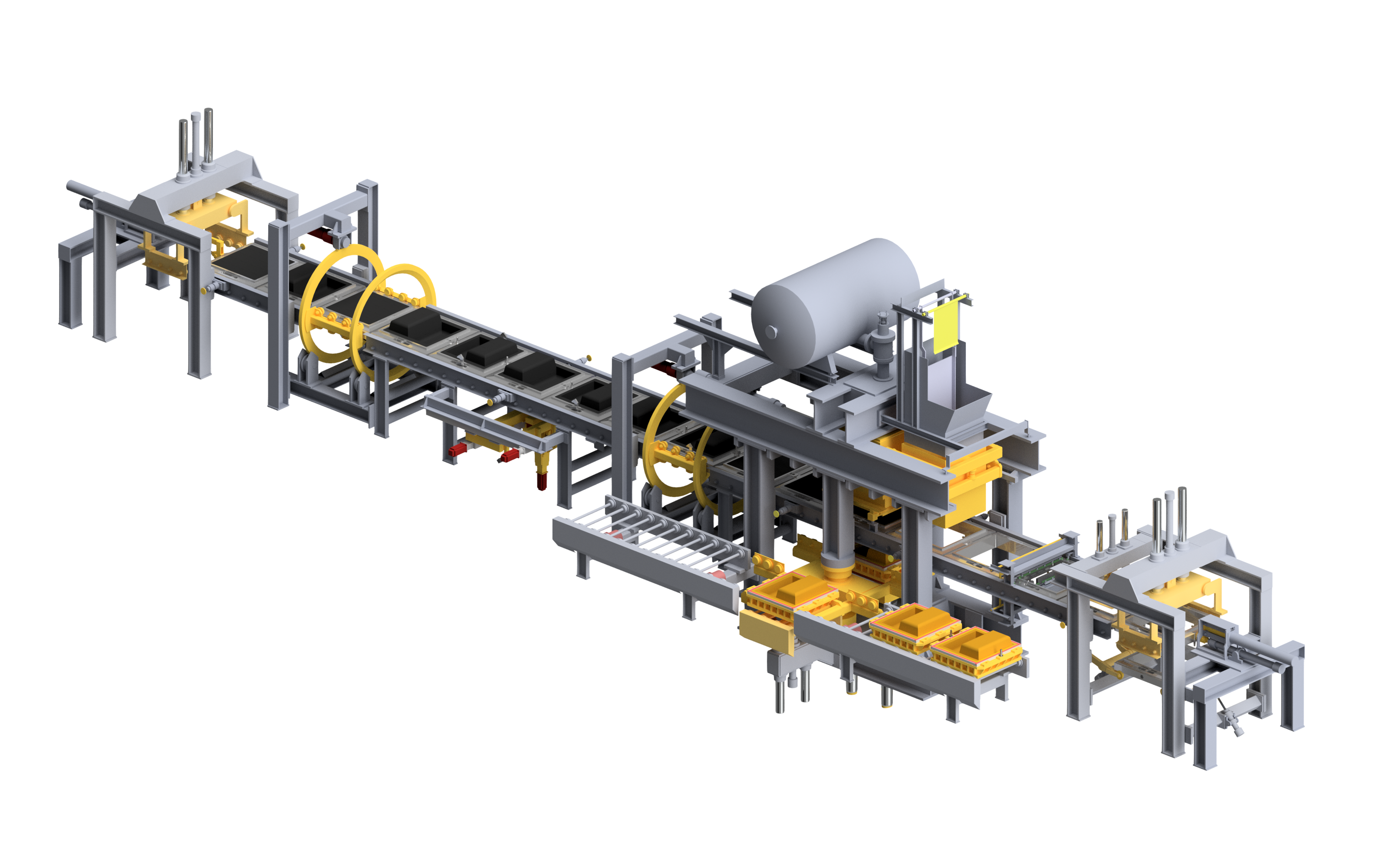

Fully automatic lowering moulding machine type EFA-S / EFA-SD

Table

Type Cpl. moulds / hour EFA-SD up to 120* *Depending on the respective moulding flask size.

EFA-S

Fully automatic lowering moulding machine with model roller track and model shuttle carriage for manufacturing cope and drag part moulds, equipped with multi-stamp press as standard equipment.

Sand filling via metering device.

Moulding flask transportation with hydraulic cylinder on roller tracks.

EFA-SD

Fully automatic lowering moulding machine with model turning table for manufacturing cope and drag part moulds, equipped with multi-stamp press as standard.

Sand filling via metering device.

Moulding flask transportation with hydraulic cylinder on roller tracks.

Technical drawing

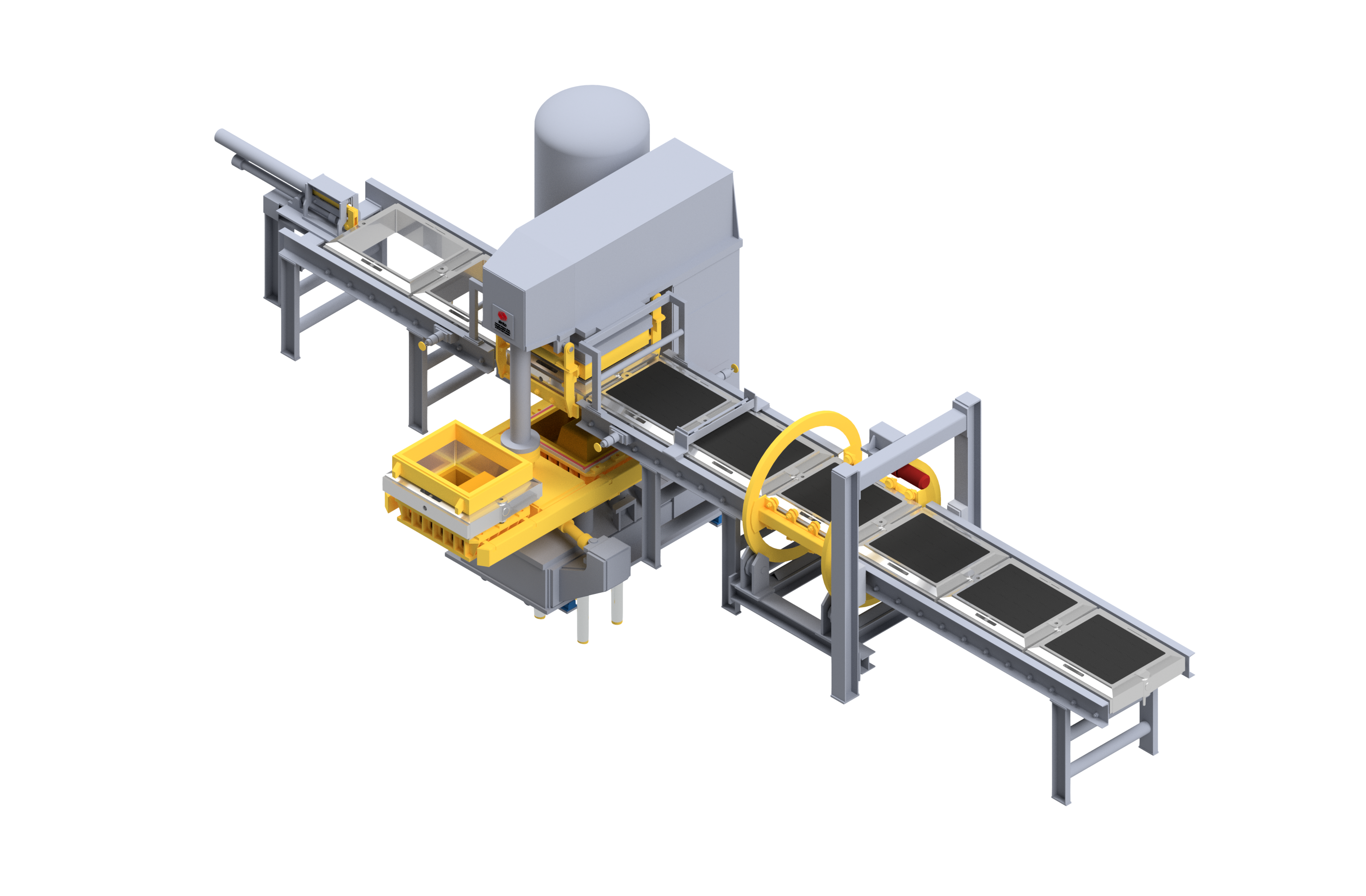

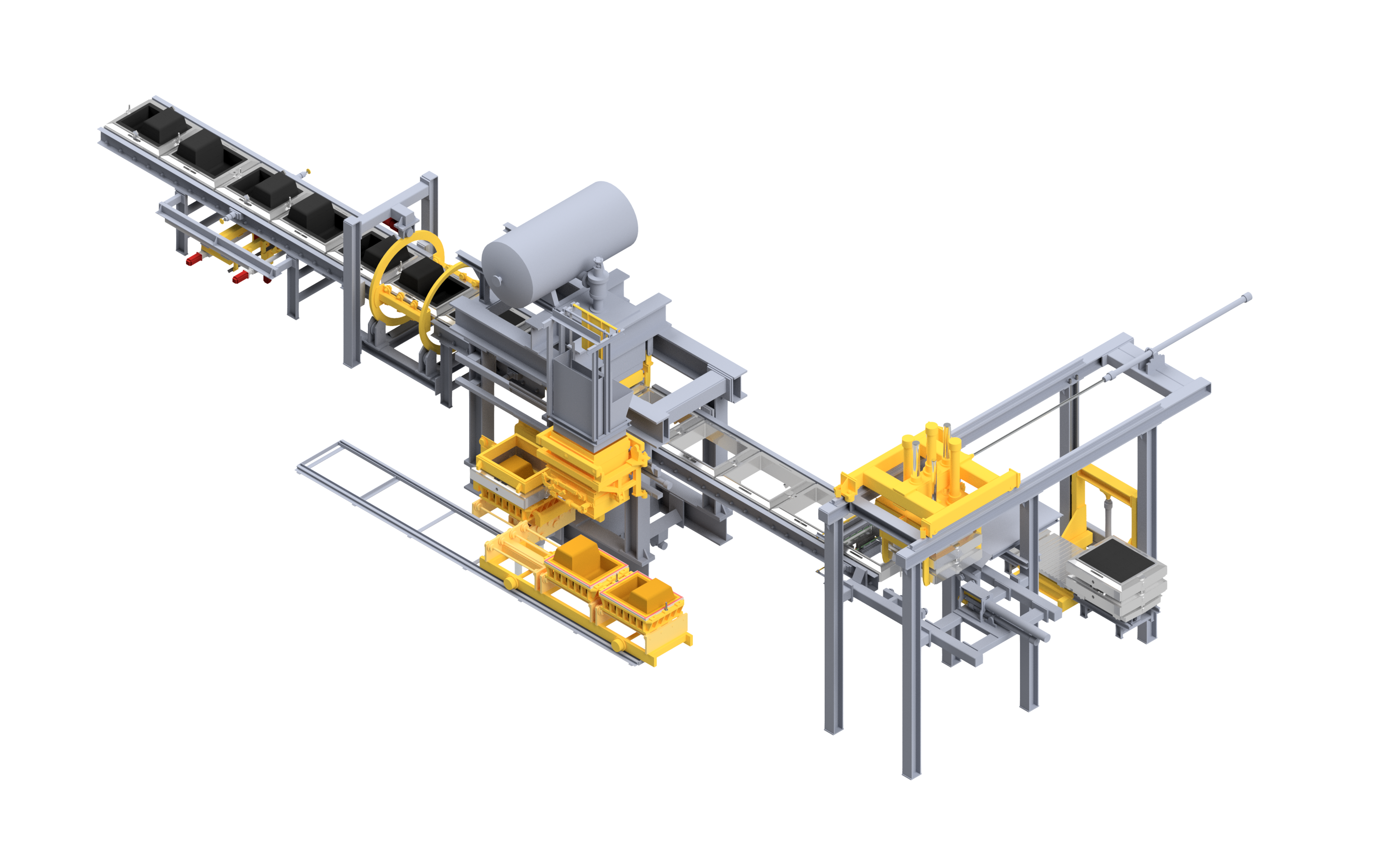

Fully automatic twin-moulding machine type ZFA-S / ZFA-SD

Table

Type Cpl. moulds / hour ZFA-SD up to 240* *Depending on the respective moulding flask size.

ZFA-S

Fully automatic twin-moulding machine for the simultaneous manufacturing of cope and drag part moulds, with model roller track and model shuttle carriage, equipped with multi-stamp press as standard equipment.

Moulding flask transportation with hydraulic cylinder on roller tracks.

ZFA-SD

Fully automatic twin-moulding machine with model turning table for manufacturing two cope part moulds or two drag part moulds or a moulding flask set, equipped with multi-stamp press as standard equipment.

Sand filling via metering devices.

Moulding flask transportation with hydraulic cylinder on roller tracks.

Technical drawing

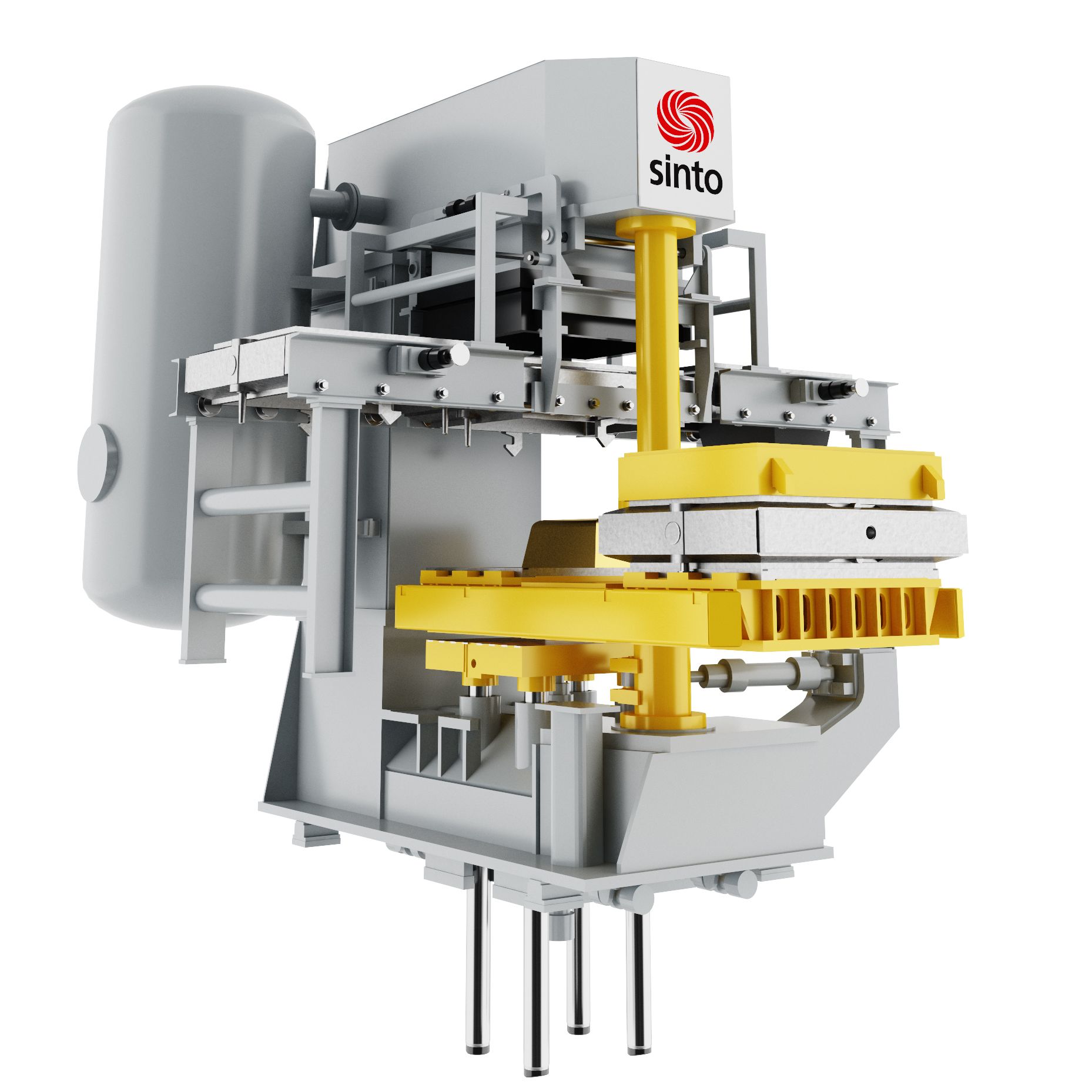

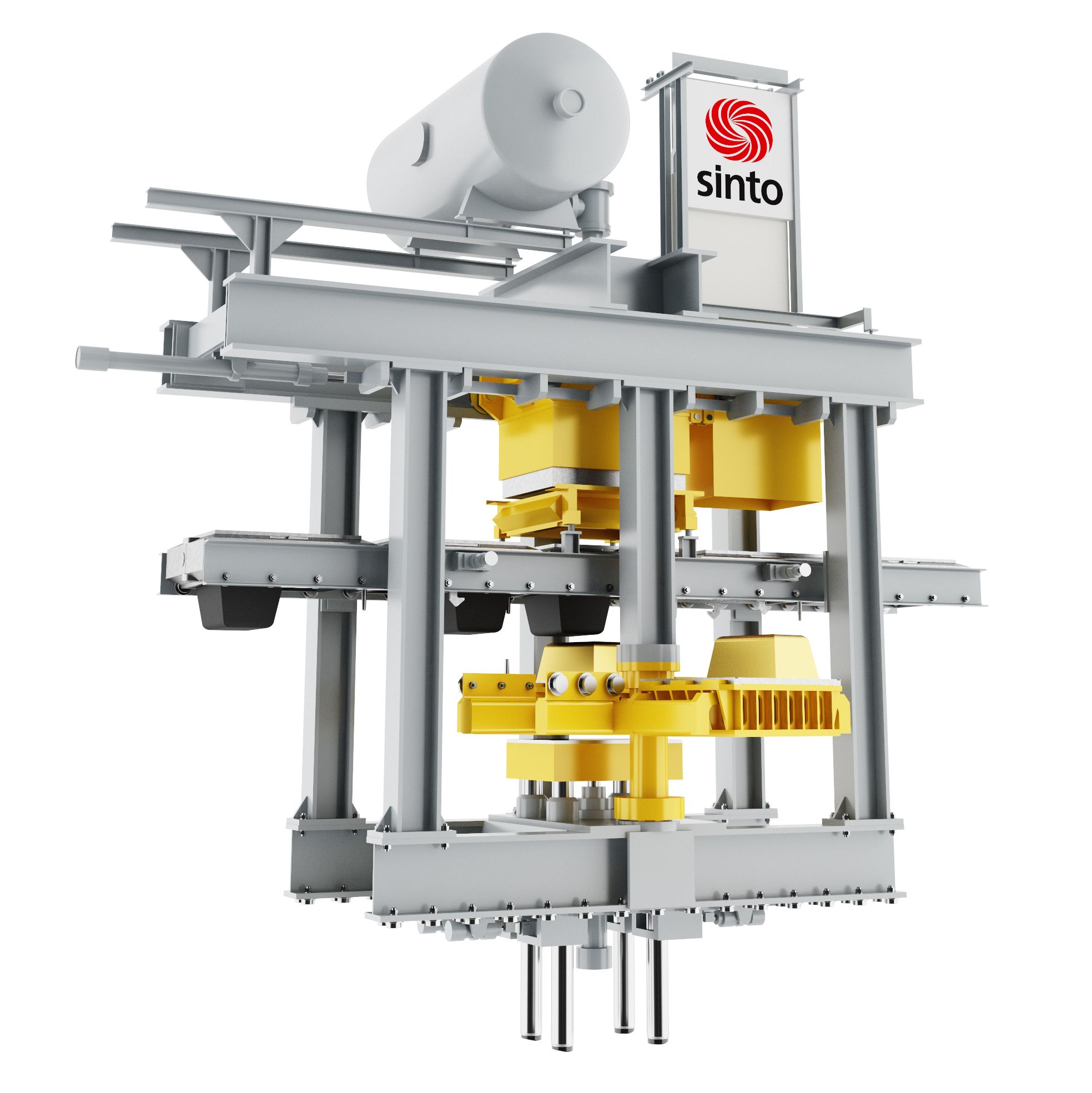

Aeration moulding machine type ACE

Table

Type max. moulding flask

interior dimensionsMoulding flask height Max. output

approx. cpl. moulds/hACE-3 700 x 500 150 – 300 150 ACE-4 850 x 650 250 – 350 150 ACE-5 1000 x 800 200 – 350 144 ACE-6 1200 x 1000 250 – 400 120 Deviations possible depending on moulding flask size.

The ACE is a close relative of the Seiatsu family of flask moulding machines from Heinrich Wagner Sinto. Through the optimised movement and action sequence, the machine achieves the shortest cycle times with low energy consumption, whilst also guaranteeing perfection in every mould.

The moulds are filled with sand fluidised by compressed air. This results in increased flowability of the sand and therefore allows more complex model geometries to be filled.

Aeration Compact Energy

With this process, the sand in a storage hopper is fluidised through air-permeable filter plates on the insides of the hopper. The sand is filled with a low positive pressure through slotted nozzles arranged on the side of the contour cylinder/cylinders. An evenly and completely filled mould is compacted through the lowering of the two main cylinders and the contour cylinder. The press on the model side closes and completes the moulding process through an additional lowering movement of the filling frame and the moulding flask is lifted from the model. At the end of the lifting movement, the hopper sand is refilled and the model change is initiated before the next mould cycle starts.

Advantages of the ACE technology

Mould quality satisfies the highest requirements

Consistently high mould strength is achieved through the various possibilities of the press on the sand ridges and model-side press. Through precise, vibration-free mould separation the ACE is capable of establishing thin-walled cast pieces with minimal mould draft angles.Increased energy efficiency

The design’s utilisation of gravitation during the pressing process increases efficiency. The energy consumption is significantly reduced and makes a major contribution to a reduction in energy costs.Reduced emission values

The noise level is less than 80 dB(A). The working environment remains free of vibrations due to the enclosed design. A hermetically sealed chamber reduces pollution caused by separating agent and dust.Metering as required – excess sand is a thing of the past

Almost no surplus sand arises during sand filling. The quantity of sand required to fill a mould is precisely controlled with a control system, so that the sand that is scraped off the rear of the mould by the sand scraper is reduced to a minimum.Compact design

With its compact dimensions, the ACE can also be installed without a foundation pit. A significant advantage when replacing the moulding machine in an existing moulding system. Minimal space requirements together with generous accessibility for maintenance are no contradiction.Sand filling that is kind to the model

The fluidised sand has a significantly less abrasive effect on the model contour and therefore results in a longer service life for the models. The resultant dimensional accuracy is reflected in the cast piece.Technical drawing