Special modules

On customer request, HWS realises all types of modules required for the moulding system insofar as technically and physically possible. In general, HWS works closely with the customer to find optimum solutions for the respective application case.

Modular pattern spraying device

Development of Technology – HWS provides a new, more efficient and modular Pattern Spraying Device

The process was developed on the basis of the customer requirements, and we are now in the process of standardising it for all of our other moulding machines.

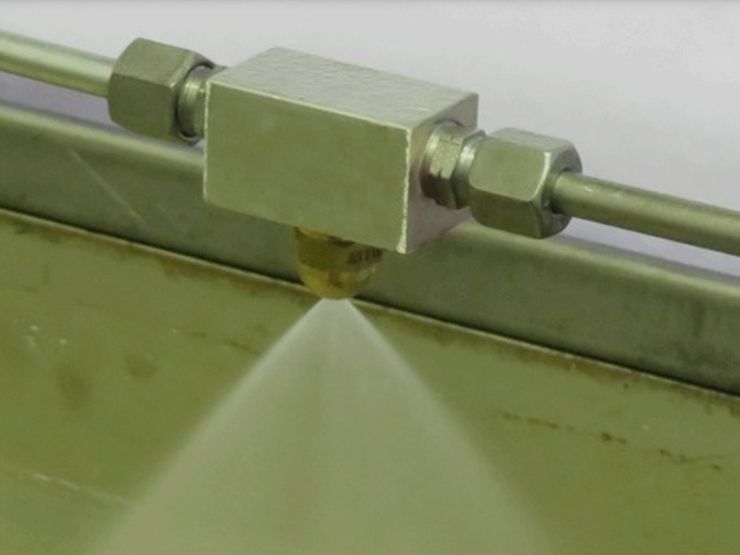

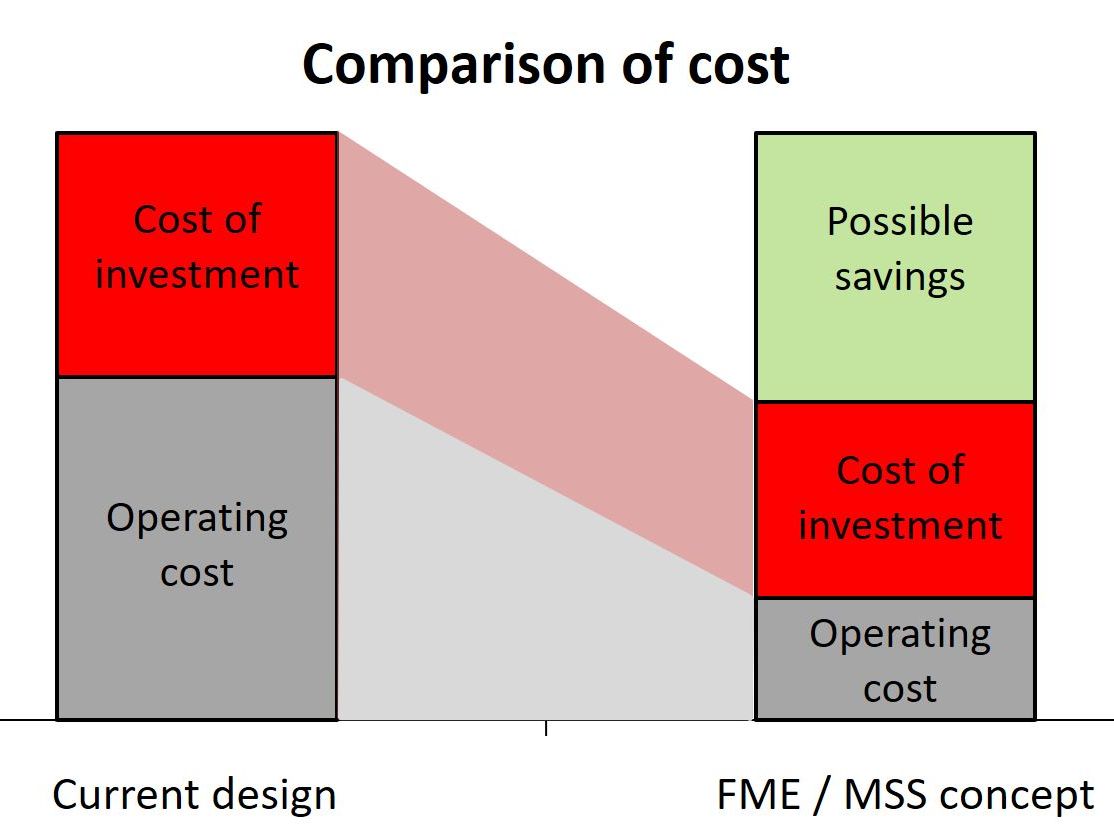

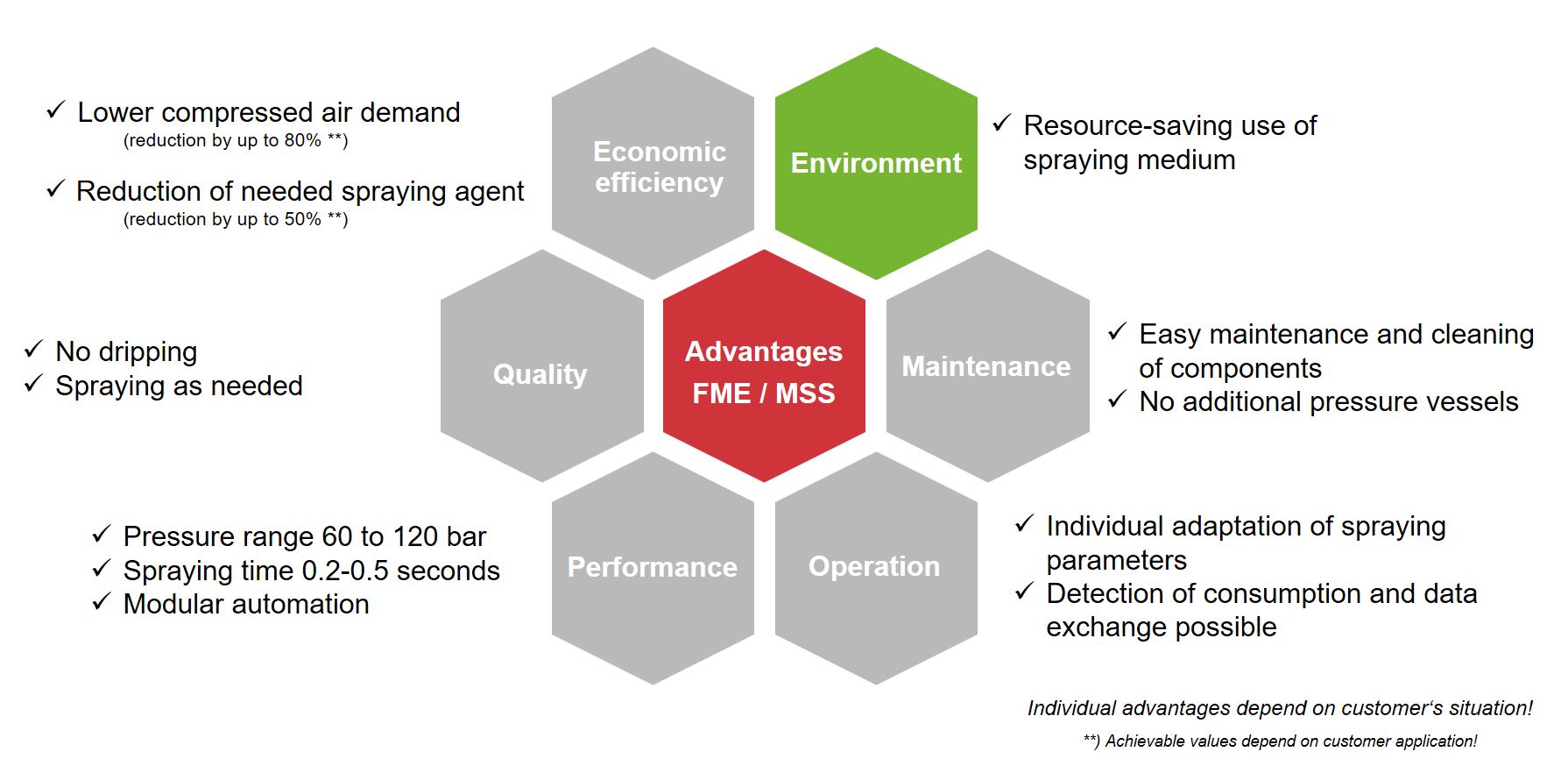

It helps to significantly improve the mould making process and to save the resources used. In mould making, spraying agent is an important indicator and with the new process, it is applied more uniformly and the need for spraying agent is reduced.The system is characterised by high efficiency in the use of the medium and by consistent spray quality, while the operating costs are optimised. Instead of producing an aerosol (current devices), it solely works with the parting agent in the high-pressure direct process. The parting agent is applied directly to the pattern by means of an appropriate nozzle and valve system. This system uses very small quantities of parting agent and also significantly reduces dripping. It is designed in such a way that no separate pressure vessels are required as reservoirs and the agent can be supplied directly to the system from storage containers.

The process can be used in various design variants for new plants as well as for existing plants. It is possible to retrofit the system to existing SEIATSU moulding machines and ACE moulding machines, adapting it to the specific machine type in a modular way. At present, good results have already been achieved in a customer application with two ACE moulding machines. A test setup for SEIATSU moulding plants is available in our technical centre in Bad Laasphe where data are acquired in order to test critical application scenarios on demand.

Test scenarios according to a customer reference showed a significant increase in efficiency due to savings potentials in compressed air consumption as well as spraying agent consumption with the same targeted cycle time and increased quality requirements.

Depending on the respective modular expansion stage, the new system also permits the integration of consumption value recording and control according to pattern-related process parameters. Another improvement is that the pump station with attached unpressurized storage container can be arranged here according to customer specifications in order to convey the spraying agent to the moulding machine by means of a media line. The reduced number of components and an easier accessibility also improve ease of maintenance.

Possible expansion stages include automated refilling of the reservoir, integration into the plant control system or data transfer for evaluation.If you have any questions or are interested in our products, please do not hesitate to contact our area sales managers or technical contact persons.

Emptying concepts for core and green sand separation

HWS has already installed a range of emptying concepts for core and green sand separation for a number of manufacturers of automotive cast parts on moulding systems. With these systems, as much green sand as possible is fed back to the sand treatment system prior to emptying the cast part at the separation unit. When the cast parts are removed, only the core sand and residual green sand are present at the separation unit.

Fine sand slinger

The fine sand slinger reduces errors in the cast part surface, which arise due to lumps in the mould sand and lead to increased cleaning work. The coarse sand is ground by a roller brush and uniformly applied to the model surface, refined with the remaining sand. The fine sand slinger can be integrated in the sand hopper of the moulding machine or arranged upstream of the moulding machine as a separate unit.

Advantages of the fine sand slinger:

- Faultless filling of tight model pockets

- Precise contours reproduced with complex model sections

- Significant improvement in the surface structure

- Improved compaction effect

Sand milling

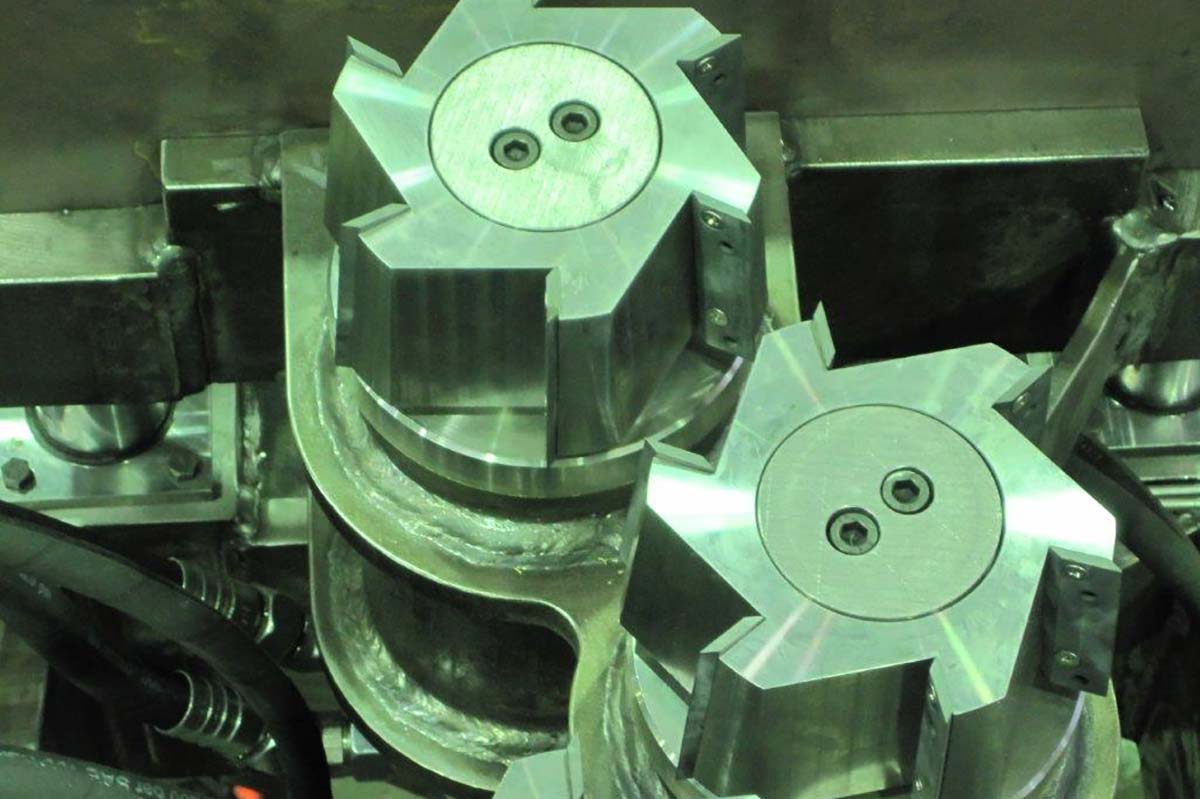

In order to attain up to 100mm overpressing of the cope part mould, HWS utilises sand milling. This mills the sand with rotating blade heads along the mould flask. The unit can be directly integrated in new moulding systems or retrofitted to existing systems.

Automatic core setting device

To guarantee cycle time and precision when inserting cores, HWS constructs automatic core setting devices. The cores are manually or automatically inserted in an insertion gauge or assembled and subsequently picked up by a grabber gauge and placed in the mould flask. During insertion, both the mould flask and the core setting device are precisely centred, to insert the core exactly in the mould.