Vacuum PROCESS moulding machines and lines

Our individual and flexible system layouts offer the optimum solution for every task. Be it fine synthetic cast or heavy-duty machine components – every system is individually planned in line with requirements. At the same time, the existing building structures and material flows are taken into account, alongside the workplace geometry. The V-PROCESS moulding machines and systems can be divided up into the following variants:

Test moulding machines

These are optimally suited for prototype production, pilot series or individual manufacture and small series of cast parts. Moulds for cast parts of just a few grams up to multiple tons in weight can be produced with these machines. The moulding process is supported by operator interventions. The moulds are handled entirely with hoists.

Attainable outputs range from one mould per day up to three moulds per hour.

Typical applications are the production of special cast parts, synthetic cast or the certification (also approval) of series cast parts.

Semi-automatic moulding machines and lines

These are characterised by a semi-automatic operating principle. All steps take place automatically within the moulding machine. Transferring the moulding flasks into the casting and cooling area, as well as emptying, take place with the aid of hoists. The systems can be expanded on a modular basis for a higher degree of automation.

These systems are optimally suited for the production of cast parts with high weights, and for small series and moderate unit quantities of cast parts from all weight classes. Attainable outputs range from one to eight moulds per hour

Typical products are wearing parts, valves and fittings for the oil and gas industry, as well as components for general machine construction (e.g. printing and textile machinery).

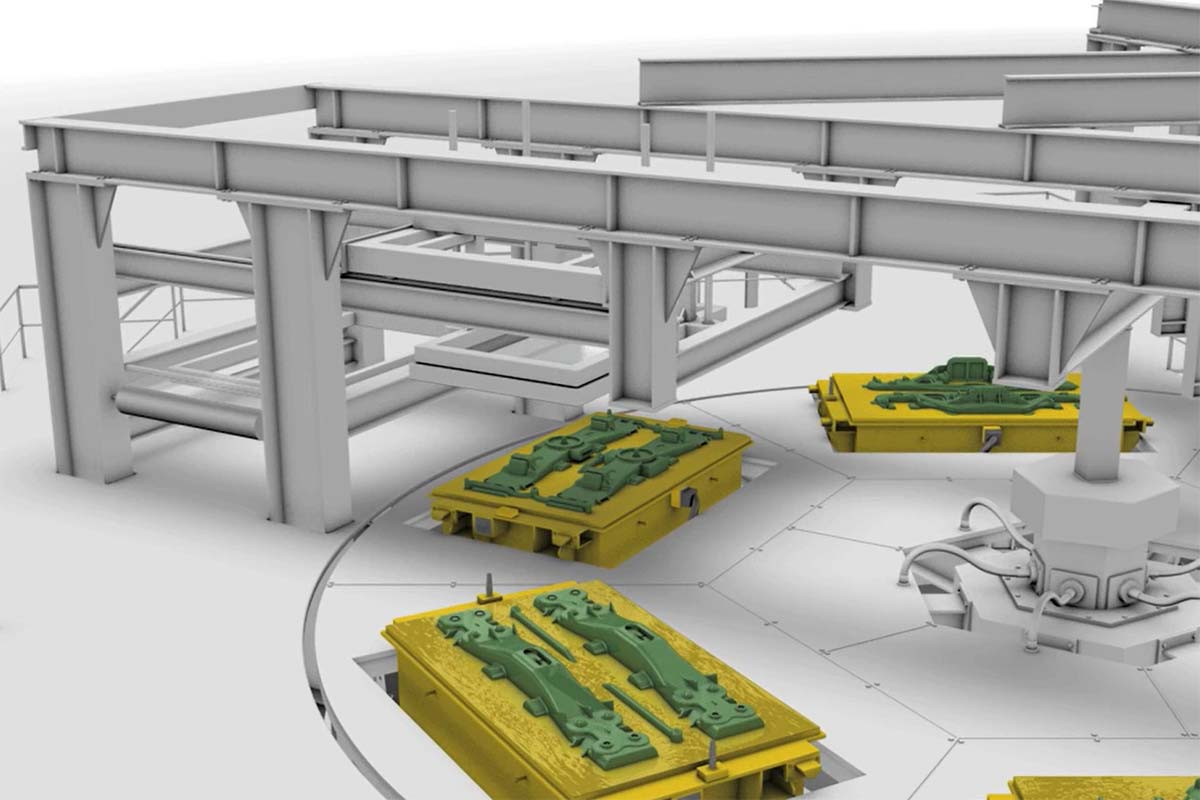

Fully-automatic moulding systems

In these moulding systems, the processes of mould production, mould transport into the casting and cooling area, and emptying all take place automatically. Standard activities on the mould, such as numbering, finishing coating or inserting the cores, can take place manually or automatically.

The efficient series production of cast parts with the minimum in manual intervention is guaranteed with these systems.

Attainable outputs range from six to sixty moulds per hour.

Such moulding systems are used for the series production of cast locomotive rails, fittings and valves, bathtubs, cast automotive parts and much more besides.