High compaction – Outstanding mould quality

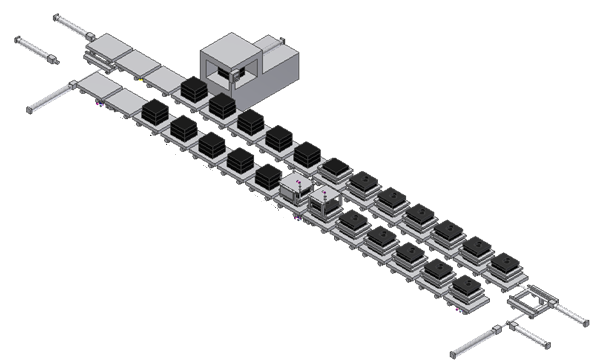

The range of flaskless moulding machines is characterised by a compact design. The integrated control system and drive technology are perfectly matched to the production process.

The turn-key moulding machine requires only a short commissioning time and stands for a rapid production availability.

An extension with individually planned mould transport systems results in efficient moulding lines.

Compact moulding machine type FDNX

Table

Type Max. moulding flask interior dimensions mm Moulding flask height Max. output approx. cpl. moulds/h FDNX 0 450 x 350 150 90 FDNX 1 500 x 400 180 80 Subject to technical changes.

The FDNX moulding machine is the smallest machine for the production of flaskless moulds. It is optimally suited for smaller cast products with few cores.

Equipped with a control system with modern operating panel, the FDNX reflects the latest engineering standard. A hydro-pneumatic compaction system complemented by sand filling with the AERATION sand filling technology, guarantees the exceptional mould quality.

The FDNX can be operated as a stand-alone machine or in a manual or fully automatic system environment.

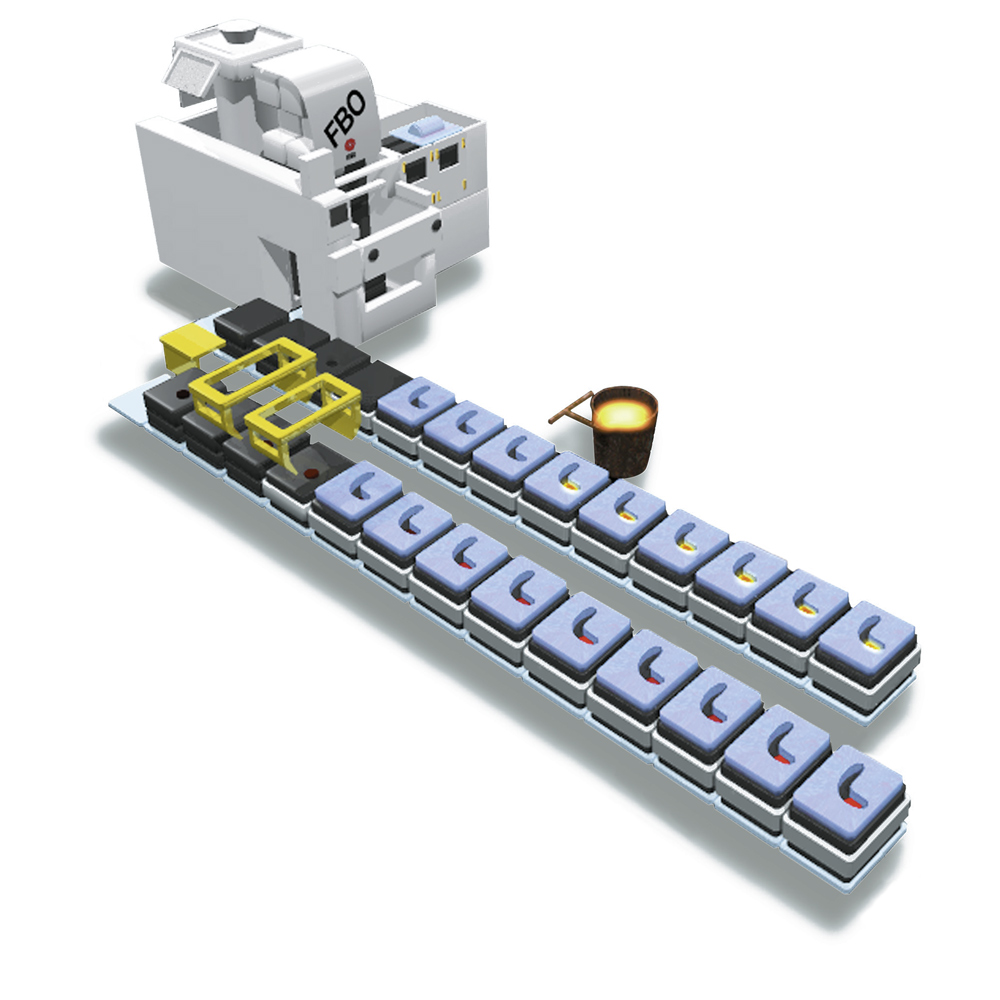

Moulding machine type FBO

Table

Type Max. moulding flask interior dimensions mm Moulding flask height Max. output approx. cpl. moulds/h FBO III-S 610 x 508 130 – 200 160 FBO IV 700 x 600710 x 610 180 – 250 100 FBO V(CE, made by SINTOKOGIO) 812 x 812910 x 710 280 – 350 100 Subject to technical changes.

The FBO moulding machine range covers a broad spectrum of cast products. With a range of machine sizes, the system can be optimally tailored to the production program.

With an ergonomically designed workstation, in particular the insertion of cores in the lower mould halves is possible. Automation is also possible in this area, to increase the performance capability.

Equipped with a control system with modern operating panel, the FBO reflects the latest engineering standard. A hydraulic compaction system complemented by sand filling with the AERATION sand filling technology, guarantees the exceptional mould quality.

FBO moulding machines are particularly well suited for use in an automated system environment.