SEIATSU.plus – Pattern-side compaction for optimum mould solidification, even with special cast products

The further development of the SEIATSU compaction process has resulted in an additional module for pattern-side compaction. This offers even more possibilities for improving the mould strength with difficult contours. As such, optimum moulding results can also be achieved with special materials, such as cast steel.

The process

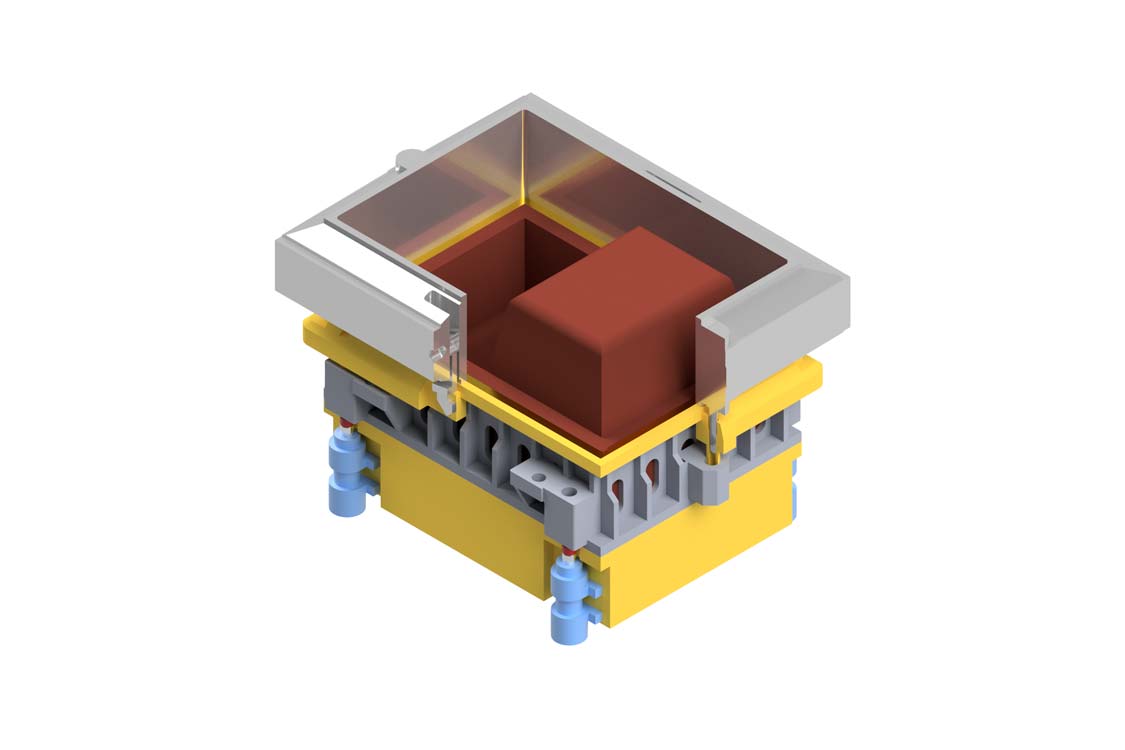

Whilst the SEIATSU airflow optimally compacts the mould areas close to the pattern, the mechanical post-compaction guarantees that the back of the mould is also compacted, so that a homogeneously compacted mould is produced. In case of low-profile patterns with narrow contours in the area between the pattern and the mould flask inner wall, mechanical post-compacting on one side does not always result in optimum mould compaction. Through application of the SEIATSU.plus process with mechanical post-compaction on both sides, it is possible to achieve a more homogeneous compaction across the entire mould.

The principle

SEIATSU.plus means when the multi-ram press is lowered, the pattern is driven to a minimal degree against the mould flask. This shearing movement results in sand compaction from the pattern side.

SEIATSU.plus is a supplementary system that guarantees optimum mould solidification with certain applications and special cast products, as well as optimised pattern allocation. Manufacturers of complex cast parts value the possibilities of the pattern-efficient “SEIATSU tool kit” combinations. Depending on the pattern, the following are applied:

- Purely mechanical pressing

- SEIATSU airflow squeeze moulding process

- SEIATSU airflow squeeze moulding process in combination with SEIATSU.plus

In accordance with the objective “as much as possible, as little as necessary”, it is possible to specifically combine the mould production with the “SEIATSU tool kit” and optimise the necessary energy use accordingly.

The advantages

High quality moulds produced with a SEIATSU mould system can often be further optimised through the use of the optional SEIATSU.plus process. The improved mould quality is particularly apparent in the edge area of the mould. Investigations by a German foundry have shown that the values for the limits of mouldability – which have been determined from specialist literature – are attained as a minimum and partially exceeded. Furthermore, SEIATSU.plus can be selected in a wide range of compaction combinations (e.g. pressing, pressing with airflow SEIATSU, pressing with SEIATSU.plus, etc.) depending on the pattern.