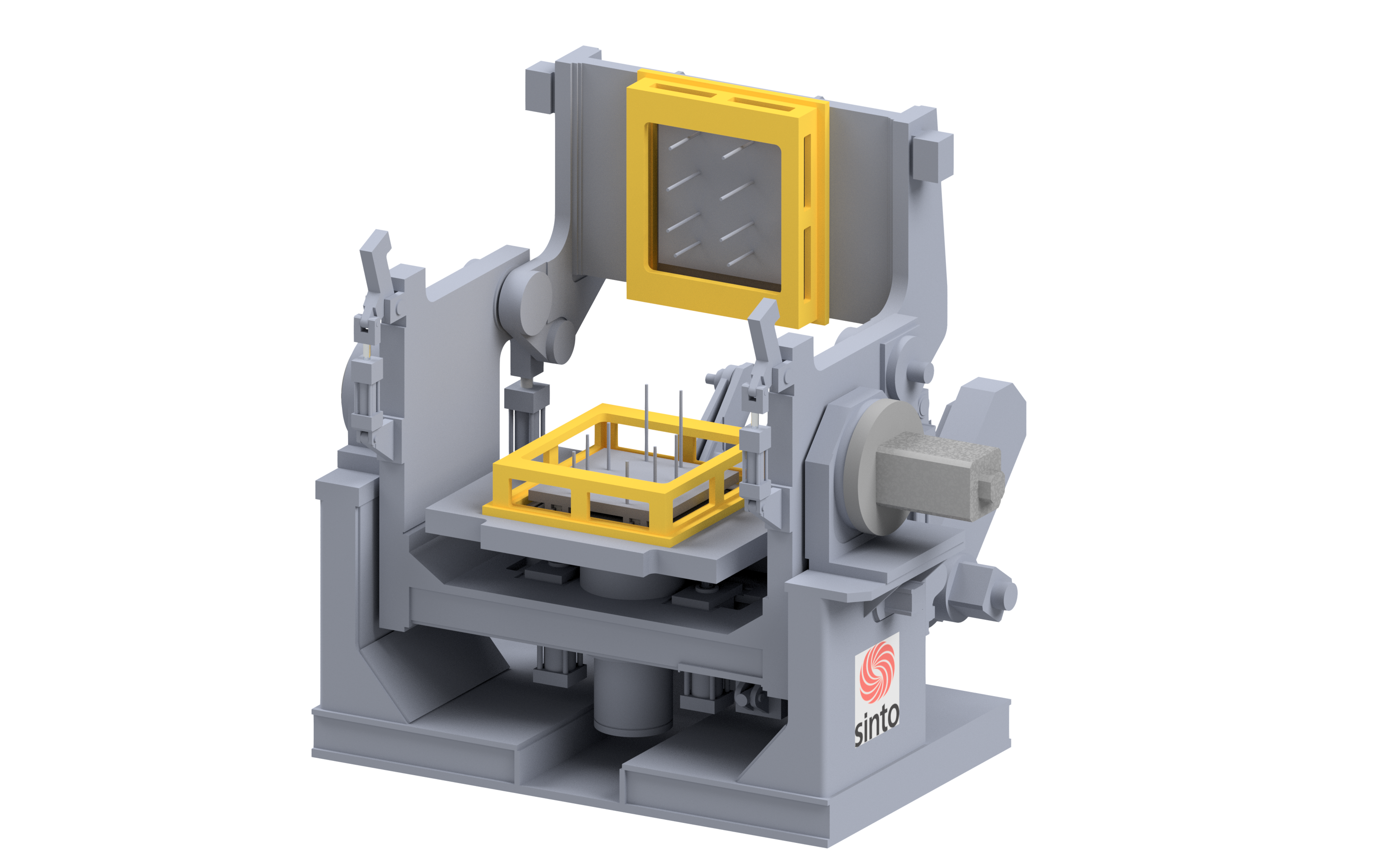

Die casting for perfect aluminium cast parts

Die casting is used for the production of light metal parts, in particular produced from aluminium alloys.

The liquid aluminium melt is poured into a permanent metal mould, also referred to as a die.

With the established casting process of low pressure die casting and gravity tilting die casting, cast parts can be produced in accordance with the highest quality demands and efficiently in a range of series sizes.

Depending on the specific requirements, the system concepts vary in their degree of automation and system scope.

Compared to sand casting, die casting delivers shorter solidification times through the use of a permanent metal mould, as well as improved material characteristics with regards to dimensional accuracy, surface quality, density, strength and stiffness.

The process

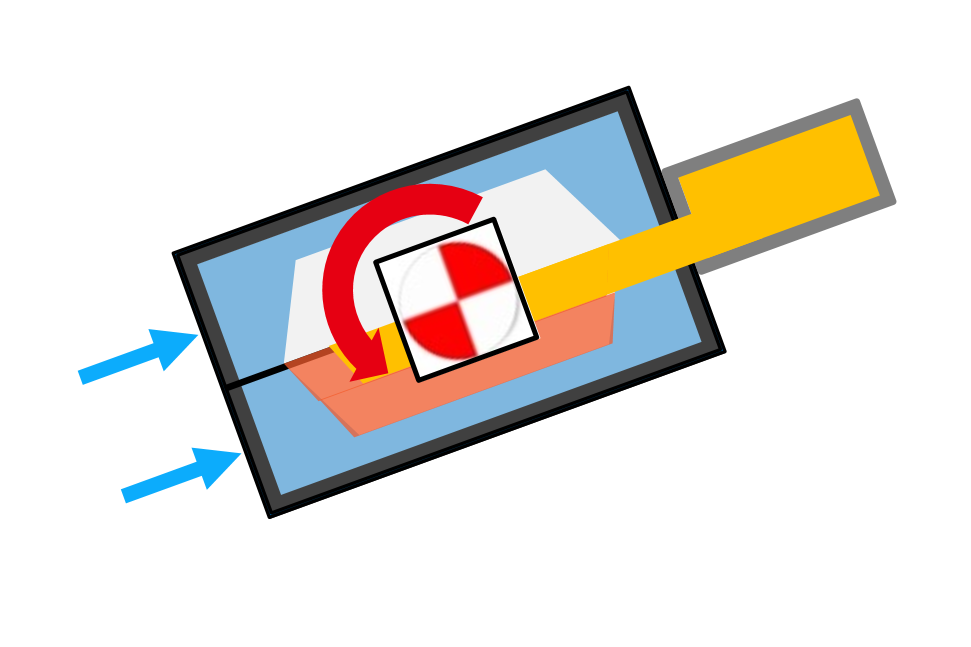

By turning the permanent metal mould through a defined tilting angle, liquid aluminium melt flows over a casting ladle into the mould cavity.

Air or water cooling supports the solidification process here.

The casting machine subsequently tips back to its default position. The mould parts are opened and the cast part is ejected.

Fig.: Schematic representation of gravity tilting die casting

The principle

The tilting movement of the casting machine ensures laminar and low-turbulence mould filling of the die.

Irregularities in the casting process and quality defects can be minimised through precise control of the filling speed.

In addition to minimal air inclusions during casting, the variable design of the tilting movement offers the option of optimising the sprue and casting processes and therefore sparing cycle materials.

With gravity tilting die casting you improve your material characteristic values, increase productivity and effectively save costs.

The advantages

- Better material characteristics through

- Uniform, controlled mould filling

- Reduction in oxide and gas absorption

- Reduction in the cycle material

- Shortening of process times through process automation and reproducibility

- Cost savings

- Better material characteristics through