Sand regeneration type USR-II

Table

USR-II Motor [kW] 37 Input quantity [t/h] max. 5 Fan [kW] 5.5 Dedusting [m³/min] approx. 60 – 100 Dimensions [mm] L 2500 W 1975 H min. 4200 Subject to technical changes.

USR-II

The HWS product for mechanical sand regeneration is suitable for freeing sand grains from any casing shells. The aim here is to achieve a condition with the reclaimed sand that is similar to new sand. This can then be used for example as a basic moulding material or as a substitute for new sand (e.g. in core shops).

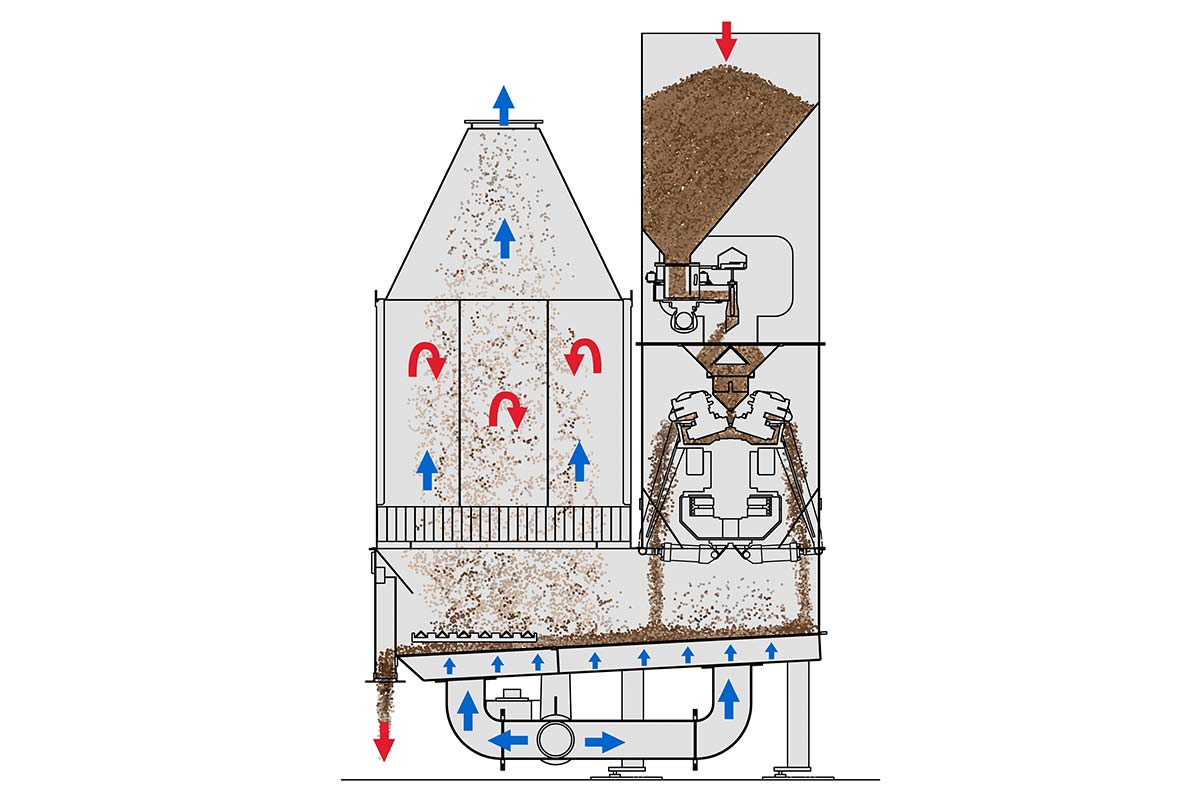

The sand is continuously and uniformly transported into the machine via a small vibration channel (no batch operation). Using a fast-turning rotating drum, the inflowing sand is transported outwards to the drum wall due to the centrifugal forces generated. Ceramic press rollers exert force on the sand layer upon reaching the target full level, and this results in the sand grains rubbing on each other. This friction process frees the sand grains of their casing shells particularly gently. The variable pressure is highly advantageous here, because the process can be aligned with the individual characteristics of the used sand. This helps to avoid grain breakage for example, and ensures a high level of regeneration efficiency.

Thanks to the use of particularly high quality ceramic components, it is possible to achieve very long service lives of the parts that come into contact with the rubbing sand. These are manufactured in the group’s own ceramic production.

The regenerated sand and binder residue are displaced by the continuous incoming flow of sand from the rotating drum, and they drop onto the fluidisation bed. This is located in the bottom part of the machine and transports the sand and binder residue onwards through the machine until beneath the deposition chamber.

A dedusting unit connected to the deposition chamber finally separates the fine particles and dust from the sand grains, which are too heavy to be extracted here. With the aid of the dedusting power setting, it is possible to realise target grain distributions here if necessary (reduction in the fine portion, dust and small grains of sand).

The high quality regenerated sand is now available at the outlet of the machine and can be freely reused in the resource cycle of the foundry.