An economical solution for diverse application areas

Outstanding mould quality and compaction are also possible with flaskless moulds. The maximum in flexibility and precision is achieved here through the horizontal mould separation level.

The process

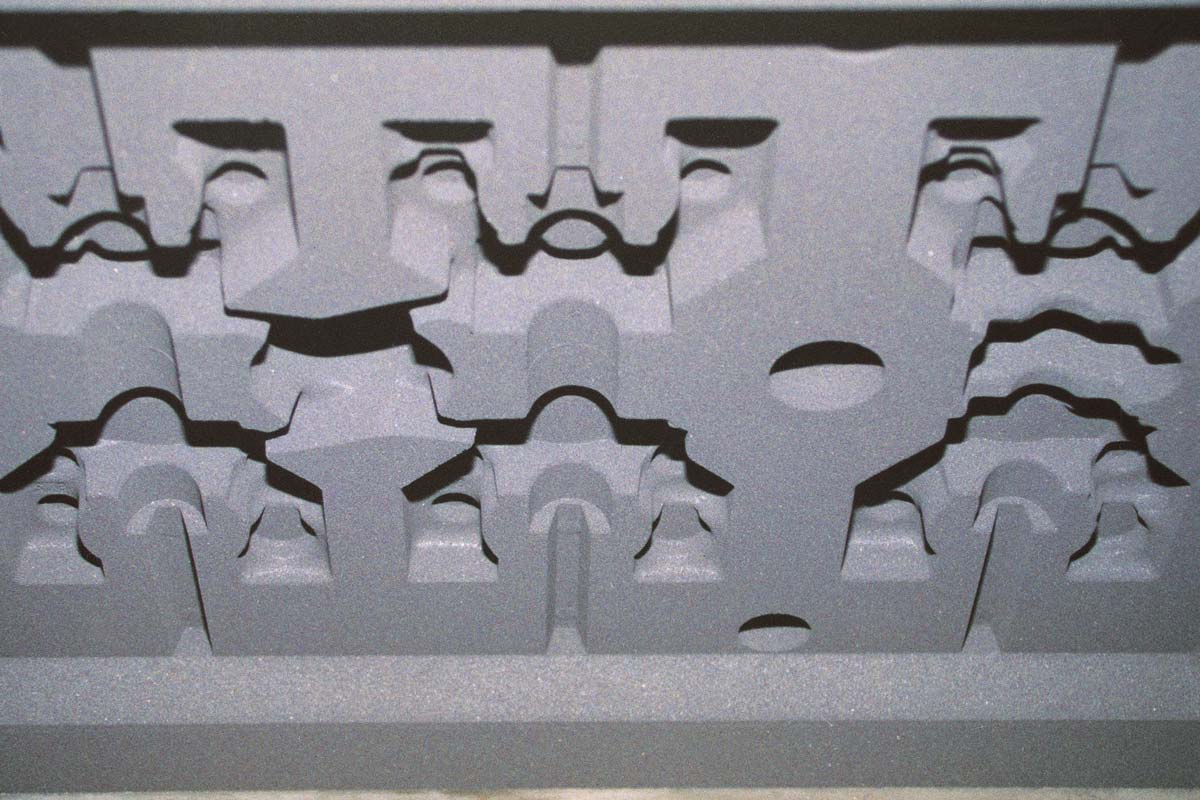

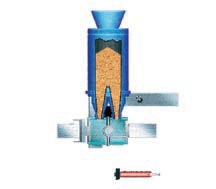

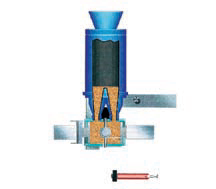

The moulding process for producing flaskless moulds takes place completely inside the moulding machine developed for this. The mould sand used is bentonite-bonded sand. The sprue and feed funnels are formed directly in the top mould half. Compaction takes place in two stages. As pre-compaction during filling with the mould sand, and in the second stage as post-compaction with pressure plates.

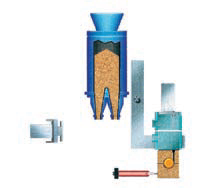

Outside the moulding machine, mould transport takes place on a system with carriage plates.

The principle

A closed mould cavity – formed from the top and bottom mould frame – is created for the purpose of adding the mould sand. Between this is the match plate with the model contour.

During the filling and pre-compaction phase, the mould sand is blown out of a mould sand container and into the mould cavity. For this purpose, the sand is rendered flowable through continuous aeration. The two pressure plates subsequently compact the mould sand. By presetting the position of the pressure plates, it is possible to adjust the variable moulding ball height.

The moulding ball is separated and the model is formed in this way. Inside the moulding machine, the moulding balls are brought together and subsequently transferred to the transport system.

The advantages

Environment

- Closed system avoids excess sand and dust

- Energy-efficient compaction

Costs

- No costs for mould flasks

- Energy savings through lower moved masses

- Compact individual system layouts

- Minimal foundation work

Quality

- Maximum precision through horizontal mould separation

- Regular compaction through opposing pressure plates

- Variable moulding ball height for optimum sand behaviour